A glued beam bath: pros and cons, projects

Many people dream of building their own bathhouse. It is a very practical and useful form of recreation. At any time a person can take a steam bath, then sit in a cool anteroom and enjoy the aroma of hot tea. You can visit a public bathhouse, but here you will need to spend money (in many places pay by the hour, you have to constantly monitor the time). And the road will take a decent amount of time. On your own territory you can fully relax and do not rush anywhere.

Features, pros and cons

For the construction of baths are used a variety of materials. Wooden bar is very widespread. Baths made of this material are divided into several types. It depends on the type of timber, which is profiled, solid and glued.

Each type of wood processing has its own advantages and disadvantages. Glued beam is the most common and takes a special place among the competitors. The baths made of this material have the best cold resistance, the wood is an environmentally friendly product. Pressed bar contains a very small amount of glue, compared to chipboard or other similar products.

Of course, a material with no chemistry at all is better, but it makes the final product rot and crack less.

The priority of glued beam in the construction of the bath.

- The beautiful appearance of the resulting product. The building from this material does not need external and internal finishing. Glued beam has an aesthetic appearance (the structure is homogeneous and smooth). Therefore, it does not need improvement in design, unlike its usual counterpart. On a simple wooden bar, you can find many cracks and surface defects that spoil the appearance of the room. Looking at the photo of a bathhouse made of glued material, you can conclude that the structure looks modern and beautiful.

- The ease of conducting finishing work. If a person still decided to make the external and internal decoration of the bath, then the work can begin immediately after the erection of the bath. Glued beam gives very little drawdown (2%). For example, a simple log sags by 20%, which can negate all the finishing work after it is finished.

- Quickness of the foundation to be erected. This element is of great importance when building a bathhouse. If the object will be made of laminated veneer lumber, then there is no need to make a massive foundation. Quite suitable is the foundation of the strip, post or pile type. This is due to the fact that the material for the manufacture of the building has a light specific weight compared to other analogs. For example, bricks and blocks have a given value of 400 to 500 kg per 1 m3 with a moisture content of 12%.

- Good quality. There are no cracks on the glued beam, the product is resistant to drying. This gives a positive moment to the owner. There is no need to putty and caulk the walls.

- Wide possibilities of use. The bar can be used during the installation of the bath of any configuration. In the building can make a different number of rooms, if desired, it is easy to make a balcony, attic.

- There is a saving of money. If you mount a wooden building with the right technology, you can avoid additional investment. You do not have to insulate the room, because the beams will be fitted tightly to each other.

- The fascinating aroma of wood. There will always be the smell of wood in a laminated bar building. This will make the parka process even more enjoyable.

Glued laminated woodblock contains chemical elements. This can be classified as a disadvantage. The presence of glue reduces environmental cleanliness and impairs the passage of air. Moisture is removed less intensively, the room does not "breathe". In addition, the price of glued beam is much higher than that of simple material.

How to choose a bar?

A bar is made of lamellas, which are stacked in the opposite direction of the fibers. They are glued using a special press, which makes the finished product particularly strong. The following chemical compositions are used for bonding.

- D3 - carpentry glue of special content.

- D4 - composition, resistant to water.

- D4 - glue with an increased content of chemical moisture-resistant elements.

- For the construction of the bath will not be suitable wood products, where the brand D3 was used.

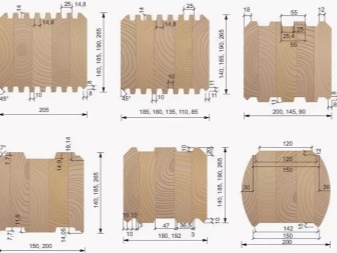

Slats are made from different types of wood. The most common are spruce and pine. Their cost per 1 cubic meter is about 20000 rubles. Lamels can be made from different types of wood. This method reduces the cost of the final product. The quality of the beam remains at a high level. Buying laminated blanks, you need to pay attention to the profile, which is:

- German;

- Finnish;

- German with a small number of spikes.

German profile is considered the best because it provides a good joint of the elements. Professionals recommend using it when building a bathhouse. German timber reduces to zero the likelihood of blowing through the structure in the corners and joints.

When purchasing glued blanks, it is necessary to pay attention to the following important points.

- The manufacturer of the products. This is a very important parameter in the correct decision-making. Buy the product better from a proven supplier, which operates in the market for a long period.

- The presence of impregnation against pests. It is better to buy a timber that has undergone such treatment.

- An important parameter is environmental cleanliness. Chemical substances (glue), which were used in production, must be harmless to humans.

- Brand of adhesive composition. It is necessary to study the reviews of manufacturers engaged in the supply of this chemical substance for joining lamellas. The glue must be absolutely safe for human health.

- The number of lamellae. The quality of the finished product depends on this indicator. A good lumber has 3 to 7 lamellae. A smaller number indicates a low-grade material.

- The end part of the product. This place should be impregnated with a special composition that protects against cracking. It is necessary to ask the manufacturer about the presence of such treatment.

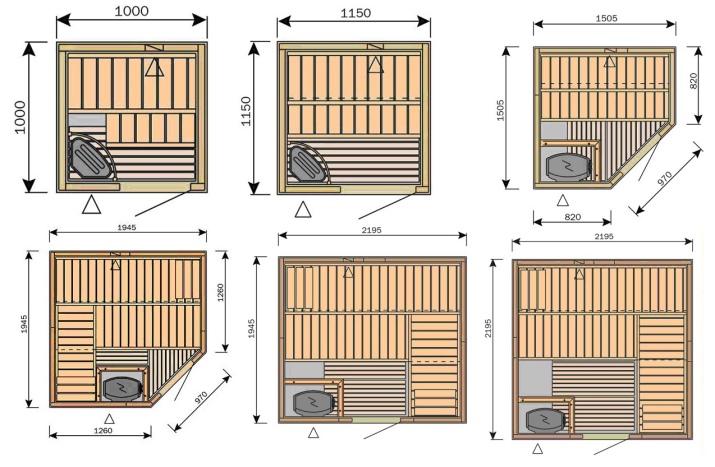

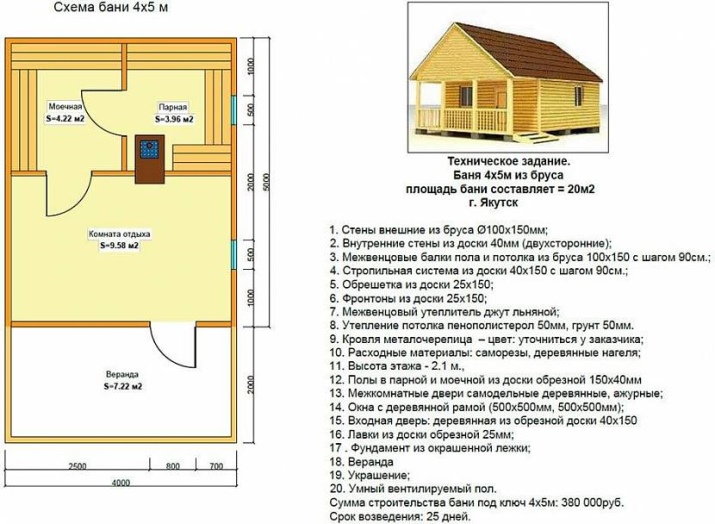

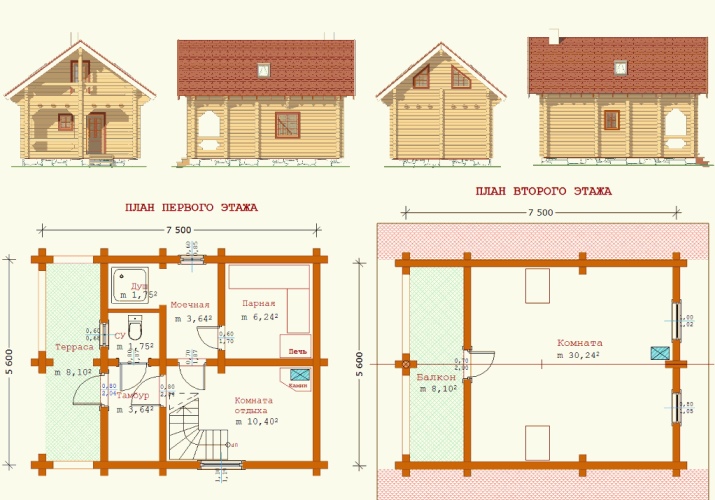

Projects

In order for the sauna to turn out elite and durable, even before the start of construction, it is important to create a competent project and plan the design. If this stage is skipped, it may lead to serious errors that will be difficult to correct. The main point in the design - it is to consider the impact of high temperatures and humidity on the materials from which the bath is made. A competent drawing will also allow you to correctly estimate the amount of materials needed and know the cost of construction. Already at the design stage you can plan the arrangement of furniture.

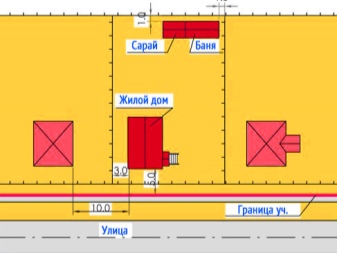

An important nuance - the choice of location of the future building. It is recommended to place the bathhouse on the leeward side of the houses. Thanks to the protection of buildings, the structure will not be hit by wind gusts and slanting rains, and therefore the service life of the walls will be increased.

If the owners have experience in construction, they can make a draft of the dacha themselves. Ready-made options can be found on a variety of thematic sites. No less convenient will be to order a special project of the bath from laminated beams. For this option will have to pay money. However, if the future owners of the bath do not understand anything in the drawings, it is better to pay for the project than to overpay for the correction of errors.

The advantage of an ordered project is that it will be made in accordance with the personal wishes of the customer and the peculiarities of the site. If the customer wants to save money, he can buy a ready-made glued-bar bath project.

Its price will be lower, however, the quality of drawings will remain at the same level, only without the individual features.

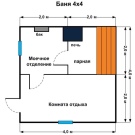

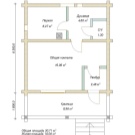

Future baths differ in size. They can be very compact - 3x4 m or, conversely, very loose (10x10). The size of the building (100, 150, 200 squares) is determined based on the size of the plot and the area that can be defined for the construction. Another factor influencing the size - the number of people that can accommodate a room at the same time. The larger the building, the more expensive it will cost to build, and operation will also require energy and financial resources.

Popular projects of the original baths with terraces, small verandas, balconies, with a second light, and some like barbecue area. In this case, the building will serve not only as a hygienic function, but also as a relaxation zone. Moreover, after the steam room is much more pleasant to be in the fresh air than to sit in a stuffy room.

Hardening is a useful procedure. The bath is ideal for this purpose, as after it you can take a dip in cold water. Owners will be very lucky if the area has a body of water suitable for swimming. Otherwise, do not get upset, because you can order the construction project with a swimming pool. It can be placed indoors or outdoors. In the second case, it is recommended to immediately plan a canopy, otherwise leaves and debris will fall into the water. At the design stage, you need to decide on the following questions:

- what materials and in what volumes are needed for construction;

- what the total cost of these materials;

- How much will it cost to build from scratch to the beginning of operation.

If suddenly the future owners of the bath have difficulties, it is better to ask for help from a professional. He will help in drawing up drawings and calculating estimates for construction. When the amount of materials required is known, they will only have to order at the factory. After receiving an order the future owners of the bath can try to assemble the structure themselves, because it is not difficult even for people who have no building education.

Construction

For the entire process of erecting any building, there are several stages. It is important to properly plan and perform each of them.

Foundation

No building can exist without a foundation. Its type and size are determined based on many factors. The main ones are the weight of the building and the depth of frost penetration of the ground under it. The most common type of foundation - strip foundation. It is easy to install, is reliable and durable. The process of installing a strip foundation takes place in several stages.

- In accordance with the future layout of the bath on the ground are made markings for the foundation.

- Excavate the excavation in accordance with the markings.

- Lay a cushion of sand. Its thickness can be from 20 to 60 cm, it depends on the characteristics of the soil.

- The formwork is fixed in the foundation pits.

- Frames of reinforced reinforcement are installed in the formwork.

- Then concrete is poured to a pre-marked depth.

- A waterproofing layer is installed.

The resulting strip foundation is a reliable structure of concrete, reinforced with reinforcement, protected from collapse by waterproofing materials. The thickness of the foundation is calculated on the basis of the soil characteristics.

Walls

Beforehand, a groove is cut in each bar. Due to the resulting notch, it is possible to fasten one bar to another, laying between them jute insulation. The first row of beams should be insulated from contact with the foundation with a layer of waterproofing material.

It is not desirable, It is not desirable for a joist wall to be longer than 6.5 metres, otherwise you will need to secure the links with vertical ties. When all the walls are erected, it will be necessary to caulk them to prevent the cold from penetrating into the grooves. Within 1.5 years after the completion of construction, the walls will shrink and the procedure of caulking will need to be repeated.

During the construction of the walls at the same time are installed gutters and downspouts, which will drain the rainwater and melting snow.

Roof

For buildings made of laminated veneer lumber, gable or single-slope roofs are the best. The construction itself includes a system of rafters, a base in the form of a lattice, insulation layers that protect against moisture and high temperatures, as well as decorative details. Before the roof is covered, decking is installed, and a gable is erected. To the resulting base is attached lattice frame, on which the roofing material is placed.

For the roofing of the roof of the bath most often used:

- slate;

- decorative shingles;

- metal sheets.

When the roofing is completed, it is necessary to equip the roof structures with gutters, gutters and eaves.

Beautiful examples

Hybrids of houses and baths made of laminated timber are especially in demand. In such a room you can not only take hygienic procedures, but also cook food and relax. At the cottage, it will be a full-fledged house, and on your own plot house-bath will be a place of permanent residence with comfort.

Combining the house and sauna will save your budget and free up space for other buildings.

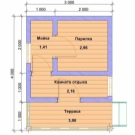

Single-storey glued-bar bath building is somewhat limited in freedom of layout and the number of rooms. The simplest interior of a one-story bath consists of a steam room, a washing room and a room for rest. If the owners want to increase the number of rooms, they either need to plan a larger area for the construction, or agree to reduce the size of each of the rooms.

The advantages of a single-story room are a small construction budget and operating costs. The disadvantages are limited space and the impossibility of combining a bathhouse with a house.

Two-story structures allow you to make a full-fledged house-bath due to the increased space. On the first floor there should be functional rooms such as a steam room, a bathroom, a shower room, and an anteroom with a firebox.

The second floor is more suitable for rooms where the owners can relax. It can be one large room or several smaller ones.

Turnkey laminated woodblock construction, equipped with an attic, is also quite popular. The internal layout can be done both in the classic version and add rooms. If the bath with a loft carefully insulated walls, floor and roof, the whole family can live in it all year round.

Glued beam is a very successful material. When using it the terms of construction of the bath will be minimal. In addition, it almost does not give shrinkage. In terms of its qualities, it surpasses standard profiled bar.

Easy processing and low weight of laminated wood allow you to satisfy any wish of the future owners of the bath. Designers offer their customers ready-made laminated bar plans. The number of such plans is quite large, so customers can find an offer for any desire.

See below for an overview of a laminated bar bathhouse.