All about the baths of expanded clay aggregate blocks

To have a sauna on a country site has long ceased to be considered a luxury. If previously this type of building was erected only from wood, today developers have found this material a great alternative - expanded clay aggregate blocks. They are high performance, inexpensive and easy to install.

Pros and cons

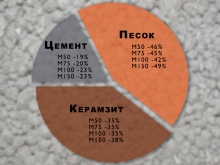

The technology of building a bath from expanded clay concrete blocks has been known for more than half a century. Thanks to this building material, made on the basis of superlight concrete, plastic cement-sand matrix and expanded clay aggregate, you can erect with your own hands durable and multifunctional structures, which have many advantages.

- Low cost. Claydite block structures do not require the laying of a reinforced foundation. This saves on construction costs up to 30%. In addition, to purchase blocks will cost much cheaper than wood or bricks.

- Quick and uncomplicated construction. Claydite blocks are hollow and have a light weight. Due to these characteristics, even a novice master can lay the material himself, just follow all the techniques. For example, to build a bathhouse on the project of 5 by 4 m or 6 by 4 m will take a maximum of one week.

- Fire resistance. Steam rooms made of expanded clay blocks, even when engulfed in flames, can stand without deformation and destruction of the frame for three hours.

- Environmental friendliness. Blocks are made only of natural materials: water, expanded clay, cement and sand. Their composition does not include chemical additives, which makes the construction environmentally safe for human health.

- Low thermal conductivity. Buildings built from expanded clay blocks, retain heat well inside, without requiring additional insulation.

In addition, claydite blocks used in the construction of baths, have frost resistance (can withstand low temperatures), chemical inertness (not exposed to mold and mildew), increased strength and resistance to high loads.

As for the disadvantages, this material is able to absorb water, because of this "wet" areas may appear on the building.

Also, many people do not like the dull and gray appearance of this building material, but this can be corrected by exterior cladding of the structure with plaster or siding.

Projects

To date, there are several options for the layout of baths made of expanded clay concrete blocks, but as a standard, any plan of construction should provide for the presence of such basic rooms as a steam room, pre-bath (locker room), rest room and shower. Steam room in such a structure is considered the most important room, it is installed shelves and a stove. The size of the steam room depends on how many people it will be designed for, experts recommend allocating for the design of this room not less than 4 m2.

A pre-bath is not necessary, but it is better to provide it, as it will prevent the penetration of cold air into the other rooms. In the washing room is usually set shower, and recreation room is arranged in such a way that it was comfortable and cozy to rest in between visits to the steam room.

If the suburban area is small and rest there is planned from time to time, then you need to choose projects of small bath size 6 or 12 m2. Owners of cottages, which used to relax in a noisy group of friends, it is best to opt for projects of baths not less than 36 m2, as attached over time, additional rooms to the building will be problematic.

Steam rooms with an area of up to 12 m2 are designed primarily for a few people, they include in their layout a small recreation room, shower room, combined with a toilet and a steam room. If desired, they can be supplemented with an outdoor terrace or veranda.

The owners of large plots of land are recommended expanded claydite concrete blocks to build not just a bath, and a two-story complex, which could be not only a good steam bath, but also to relax, relax. So, projects of baths 8,5 by 9,5 m are very popular.

Besides the main rooms (rest-room, antechamber, washing room, steam room) they also have a bathroom, kitchen, bedroom, covered terrace and BBQ zone.

On the first floor are arranged all the rooms necessary for bathing procedures, and the second - is equipped with a comfortable area for rest. To such a gray and modest construction fit perfectly into the overall view of the site, you need to hide expanded clay aggregate concrete blocks under the beautiful lining of natural solid wood, plastic, or to cover the walls with siding with imitation stone.

Step by step instructions

You can easily build a sauna of expanded clay concrete blocks with your own hands, without the help of specialists, but you need to properly comply with all the technologies. Construction of such structures is staged and begins with the preparation of the project and cleaning the area from grass, stones, trees and debris. If there are small elevations and pits on the site, they are leveled and filled. When everything is ready, then proceed to the main work and finish everything externally and internally.

Preparing

Before proceeding to the direct construction of the bath from expanded clay concrete blocks, it is necessary to make a calculation of the material, for this it is necessary in advance to determine the options for decorative finishing inside and outside of the building. In addition, it is necessary to additionally purchase material for laying communications. Once the blocks are delivered to the site, they are unloaded on pallets at a distance of 10 m from the future foundation.

Blocks should be carefully examined and cull those in which expanded clay for more than half the area of the lateral surfaces.

Foundation

Buildings of expanded clay aggregate concrete blocks are usually erected on the foundation strip, for the preparation of which you can use rejected blocks, which have small variations in geometry. This material is characterized by high thermal insulation, but requires additional waterproofing base substrate.

For this purpose, it is recommended to cover the blocks with polypropylene film and mastic. If it is planned to build a bathhouse of less than 9 m2, the blocks can not be poured with concrete mortar (it is enough only to fill the cracks and joints with a dry mixture of sand and cement). For the construction of large buildings, the strip is necessarily poured with concrete.

When building baths in regions with harsh climatic conditions, you need to insulate the site before you start laying the blocks. The laid ribbon is rolled up with roofing felt from the outside, then the material is folded up and fixed on the basement with its edges. The first row of strip foundation is laid on cement mortar, in which plasticizer must necessarily be added. The thickness of the mortar should not exceed 3 mm.

In order that the basement of the building in the future will not suffer from excess moisture, the first few rows of the basement can be laid with red solid bricks.

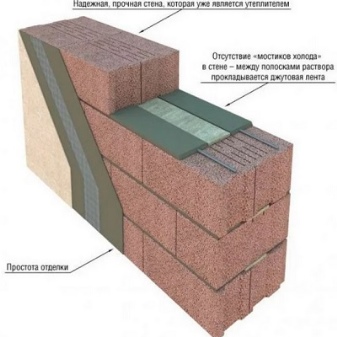

Masonry walls

Erect the walls of the future bath should begin with pulling a rope and installing beacons. After that you can lay the first row, using cement mortar, the thickness of which should not be more than 3-4 mm. Remains of the mortar are removed with a trowel. The second and third rows are similarly laid out the first, then you need to put a metal mesh on the mortar and continue laying the remaining rows. It is important to note that the grid must be placed every three rows. Do not also forget about the installation of "pockets" for mounting the floor and ceiling beams, the last row is laid out with solid blocks.

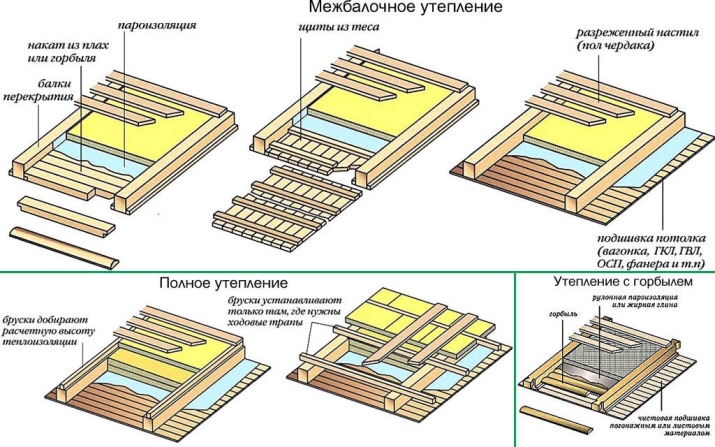

Roof installation

For expanded clay concrete baths, usually choose single or gable roofs, with the latter being considered the best option. As a material, you can choose corrugated sheet, roofing felt, tile. The installation of the roof should begin with the assembly of rafters, which are trimmed with boards. Do not also forget about the heat, vapor barrier, after the laying of which the roofing material is mounted.

Roof installation

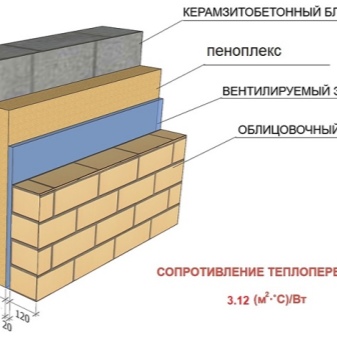

Claydite blocks have a high permeability, because of this, any flow of air blowing around the walls of the structure can make the heat quickly escape through the porous surface of the material. To prevent this, you must be sure to insulate all surfaces of the structure inside.

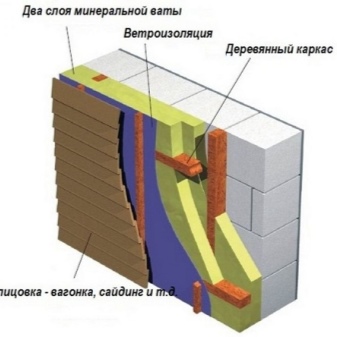

It is not recommended to install thermal insulation on the outside, as it may contribute to the accumulation of water vapor inside. Baths made of expanded clay concrete blocks are best insulated with mineral wool, it is laid in two layers, covered with foil on top, forming a ventilation gap.

Rest room, vestibule (vestibule) and showers (non-hot room) is good insulation foam thickness of 50 mm. Reinforcing mesh is placed over this insulator, and then you can perform decorative tiling or plastering. Thanks to such insulation air will not leak through the seams and pores of expanded clay aggregate concrete.

For additional insulation you can also blow out the joints with installation foam.

Finishing options

To improve the appearance of the bath, built of blocks, it is necessary to perform internal and external finishing. This will create the effect of home warmth and coziness in the rooms. Exterior cladding will give the building a stylish appearance, through which it will fit perfectly into the landscape design of the site.

From the outside

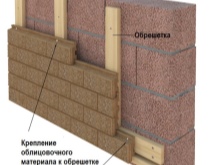

For the exterior design of baths made of expanded clay concrete blocks is well suited cladding with clapboard. Before you begin the decorative trim with cladding, you need to mount the battens, using bars with a thickness of 5 cm. After that thermal insulation and foil is laid on it. Fibreboard should be fixed to the battens in such a way that an air gap is left between the battens and the insulator.

Not bad also look buildings with facing brick and plastering, with the latter option is considered more affordable. For plastering, cement mortar is prepared, it is applied in one layer, after the complete drying of which the grouting is performed. A day later, the second layer is applied and grouted, then wait for drying out and proceed to painting.

From inside

After the sauna is built and all the exterior work is done, the most important moment is the finishing of the rooms inside. The walls and ceiling can be simply covered with clapboard, having previously prepared the base (plastered with cement-sand or gypsum mortar). As for flooring, you can lay a "warm floor" and tiling on top.

Interior finishing of the steam room is usually done with bricks or natural stone.

Ready examples

To date, there are many projects of baths made of expanded clay concrete blocks. Some of them provide for the construction of only seasonal buildings, and others - full-fledged residential complexes with a steam room and a recreation area. Among the most popular projects are those that are presented below.

Sauna with a 36 m2 terrace

This option of building is ideal for large plots of land. The project provides for a small hallway, antechamber, bathroom (shower room with toilet), steam room, recreation room, utility room, kitchen and outdoor terrace (for cooling in summer). The most important room in this construction is considered a steam room, it is equipped with a stove, heater and comfortable benches. In the back room are placed cleaning equipment and various bathroom accessories. As for the rest room, it should be equipped with everything necessary for a full and comfortable rest. In such a room it is appropriate to arrange a zone for board games, home cinema and billiard room.

Furniture items in the bath should correspond to the general stylistics. If finances allow, then in the recreation area it is recommended to put a table with a marble table top, upholstered chairs and sofas made of natural wood. In the anteroom you can put a laconic set, consisting of a small table and benches. Separate attention should be paid to the design of the terrace, where in the future it will be possible after a stuffy steam room to relax and cool the heated body. Those who like to barbecue, next to the veranda is recommended to install a separate area for barbecue, pre-lighting.

Steam room 24 m2 with a swimming pool

Since the construction is not large, the external location of the pool is suitable for it. Due to the presence of a reservoir of cold water, it will be possible to quickly cool the heated body in the steam room. Such "shock therapy" is considered very beneficial for the skin. As for the layout, then in such a bath provides a small kitchen-dining room, locker room, steam room, cheap with a toilet and a rest room with a sleeping place.

Interior finishing of the rooms is best done with clapboard, giving preference to light shades. Externally expanded clay masonry blocks can be clad with siding with imitation beams. The interior of the rooms should be decorated in a minimalist style, it is desirable to leave a lot of free space. For decoration, you can use bouquets of dried flowers in clay pots, brooms and woven carpets.

The following video shows you the construction of a bathhouse made of expanded clay concrete blocks with a slate roof and a weather vane.