What material is it better to build a bath?

The dream of most owners of country plots is their own bathhouse. It is not just a place for washing, but also an area for health-improving procedures - hot steam opens pores, normalizes blood circulation and charges vitality. About what materials should be used to build baths, and we'll talk in our article.

Features

The owners of dacha and homestead plots, planning to build a bath, inevitably face the question of what material is better to build a steam room. It is extremely important that in this room it was possible to maintain a healing microclimate both in warm and in frosty seasons without much cost. The classic material for the construction of the Russian country baths was wood. In earlier years they used peeled from the bark logs, over time they were replaced by timber. Today it is widely practiced the construction of frame structures, where natural wood is combined with some other materials.

At the peak of popularity is still burnt brick. However, in recent years, many affordable analogues have appeared - these are foam blocks, as well as aerated concrete and cinder blocks.

When buying building materials, it is necessary to take into account the fact that the inner walls of the bath are constantly exposed to temperature jumps and heated air from inside. That is why the right choice of material will guarantee the longevity of the construction.

Pros and cons of different materials

Each of the materials used in construction has its pros and cons, let's dwell on them in detail.

Brick

Brick in the construction of the bath is used for quite a long time, and this is due to its undoubted advantages:

- long operating period - Brick buildings can be used for more than 100 years, while the lifetime of wooden baths does not usually exceed 20-30 years;

- aesthetic appearance - Bricks look very stylish and can be used to create any design solutions;

- high fire resistance - brick is not exposed to the action of the flame, it is advantageous compared to wood.

At the same time, the use of bricks for the construction of bath structures has a number of disadvantages:

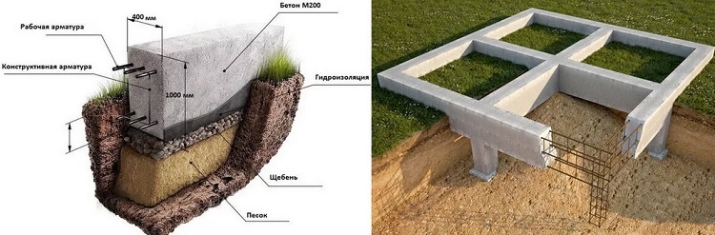

- due to the high weight of bricks, the construction requires the construction of a strip foundation - this is quite a long and expensive procedure;

- Warming up a brick takes quite a long time: While a wooden bath can be heated up in 1-1.5 hours, a brick building will take 3-5 hours and will require much more fuel;

- Brick surfaces are very poorly permeable to air, so mandatory forced ventilation is required in such baths;

- High cost of works and a long construction period - when building a bath, you will have to wait for the concrete to fully dry, and laying the surfaces also takes a lot of time.

Stone

A stone bathhouse looks very fundamental and impressive. This material has many advantages. First and foremost is the fire safety of stone, as well as its low shrinkage - it is only 5%. Stone is available for sale and has a low cost with a long service life. At the same time, it has a lot of disadvantages, so it is not widely used in the construction of baths. One of them is the difficulty of construction - the stones are irregular in shape, so it is difficult to create a stable structure. In addition, the stone does not retain heat, so it needs reliable insulation, as well as requires increased fuel consumption when igniting the furnace.

In addition, Stone buildings "do not breathe", on their walls appears wet condensate - to eliminate such a drawback is possible only with a powerful vapor barrier system and the organization of forced ventilation. Stones have quite large dimensions, so the thickness of the walls of such a bath is large - on average, not less than 75 cm. For comparison, the thickness of masonry is only 51 cm, and the thickness of wooden walls does not exceed 20 cm.

Such an impressive size and great weight requires a strengthened foundation. As a result, the construction of such a bath is quite expensive, despite the fact that the material itself has an affordable price.

Blocks

In the last decade, building blocks have firmly established themselves in the market of bath structures. Their popularity is explained by incredibly short construction terms while maintaining a democratic cost of the work. The most common are several varieties.

Aerated concrete .

This material is made from cement and quartz sand with the addition of blowing agents. The outside of the products are covered with special impregnations, so that they are given increased strength. The advantages of the material:

- fire resistance;

- high strength;

- low weight;

- ease of cutting and drilling the material.

The main disadvantage of aerated concrete is its high cost, as well as the ability to absorb and retain moisture inside itself - the construction of the bath from this material will require an additional layer of vapor barrier.

Claydite concrete .

Represents modules on the basis of expanded clay, cement, as well as foamed and additionally baked clay. The main advantages of the material include:

- low thermal conductivity;

- low water absorption;

- absence of shrinkage;

- low weight.

A sauna of expanded clay concrete needs a small amount of insulation, because the resistance to low temperature of this material is 5 times higher than that of aerated concrete. This allows you to achieve the longest service life of the building.

Cinder block

One of the cheapest building materials, which is made by pouring concrete lumber, products of coal combustion and other wastes. Pros of the material:

- long service life - such baths can stand for at least 50 years;

- effective protection against fire;

- affordable cost - the price of cinder blocks is several times lower than that of wood and bricks;

- Different variants of filling - thanks to this, each user can choose the best solution for themselves.

The disadvantages of cinder blocks include their high hygro-sokpichnost, so the material needs additional waterproofing. In addition, the disadvantages are the high thermal conductivity, which necessitates the installation of thermal insulation.

When working with cinder blocks one should keep in mind that before the construction it must be aired for at least a year, because of this construction may be delayed.

Lafet

Lafet is a log, planed on both sides, its sides are made aligned and straight. The Norwegians were the first to use lafet for the construction of the baths - it was they who developed the lock connection, which provides a high degree of heat retention and exceptional durability of the structure. The material is widely demanded for the arrangement of bath barrels. The advantages of loft include a number of factors:

- environmental safety - the wood does not contain any toxic ingredients glue components;

- Increased strength - the fixation is made with the Norwegian lock;

- high level of heat preservation - logs are adjacent to each other without gaps and cracks, so heat loss is minimal;

- the carriage looks very stylish, so it does not require additional decorative trim;

- The light weight of the structure allows you to do without the construction of a powerful foundation.

At the same time, there are some disadvantages:

- The need to impregnate wood with antiseptic and hydro-resistant compositions - logs have an open core, so the likelihood of rotting increases many times;

- The total cost of the structure of the carved wood will be higher than the construction of the bath from a simple beam and log.

The most difficult moment in the construction of baths and saunas from carpentry is the design of the castle connection. The optimal solution would be to purchase prefabricated structures.

Most companies these days offer a similar size blanks with locks, so all that is left to the owners of the land - just collect them from the bath.

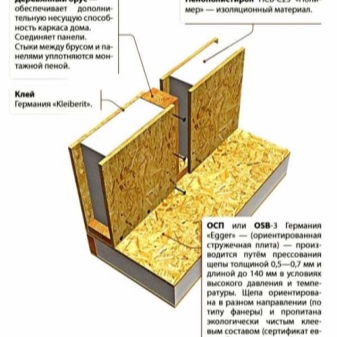

OSB

Sheet oriented chipboard that is used in the construction of outbuildings. It is an inexpensive material, most often goes to the rough finish of technical facilities. In baths, it is allowed to install it in the hostel, as well as in the vestibule. In the shower, and even more so in the steam room to use the boards is strictly prohibited. The fact is that this material is made by pressing with the addition of formaldehyde resins. Under the influence of heat and their vapors settle in the room - as they accumulate, they worsen human health and significantly increase the risk of cancer.

Alder

Alder is often used in the construction of baths. Of course, Alder-tree has a rather high price compared to other types of wood, but its quality is invariably high. Alder wood gives little shrinkage and has a beautiful reddish hue. Alder is easy to work with because it does not twist during installation. The only disadvantage of alder is its susceptibility to rotting, as well as the change in color during use.

Aspen

This material has a high degree of density and moisture resistance, in addition, it gives very little shrinkage. Aspen is characterized by a long service life. Of the disadvantages we can note only the high cost of the material.

Fir

This type of wood is very rarely used in the construction of baths, as it has a low resistance to water and low strength. In addition, the material is quickly subjected to rotting.

Lime

Working with linden in the construction of the bath is very convenient and easy. It is characterized by a high level of heat resistance. However, you should consider the fact that this material requires mandatory finishing and impregnation with special compounds, because in the process of use under the influence of hot steam lime often darkens.

Other

Another wood material that is often used in the construction of baths is pine. This species is naturally protected against insects and mold in the form of resin. You can buy pine at every construction market for a reasonable price. However, in conditions of high temperature pine begins to "cry", so it requires additional treatment with fungicidal preparations that prevent rotting.

In Soviet times, arbolite was often used to build bathhouses. This material is a block, which by 95% consists of waste wood. Such a block is obtained with the help of a crusher or chipper, these constructions should be poured with cement based on liquid sodium and calcium - the use of these components allows to repeatedly accelerate the hardening of the solution and protect the wood from deformation.

The advantages of arbolite blocks include:

- low thermal conductivity;

- environmental friendliness of the material;

- affordable price;

- hygro-resistance.

Heat capacity of this material corresponds to the air, so in the arbolite sauna first warms up the air mass and only then the surfaces are heated. In comparison, in brick buildings it is vice versa.

Selection criteria

Choosing the material for the construction of the bath, you should know that the construction of any objects on private property should be regulated by SNiP 30-02-97. Requirements for the construction of the bath, much stricter than for houses and other household buildings. Criteria, which should meet the material for the installation of such structures, not so much, but if you do not pay them due attention, at best the bath will not give the expected effect, and at worst - will harm your health. The material for the construction, in addition to the requirement of exceptional strength, must meet a number of other requirements:

- high thermal insulation properties - this is important for maintaining an optimal microclimate;

- resistance to high humidity and significant temperature fluctuations;

- fire resistance of the material, incombustibility;

- environmental safety, no volatile toxic substances under the influence of hot steam.

In addition to the above criteria, the choice of building material directly affect the size of the future structure, as well as its location on the site. And, of course, the financial capacity of the owner.

Tips

When purchasing materials for the arrangement of the bath professionals advise to focus on several factors. If you are critical to the cost of construction - it is better to give preference to a wood of natural humidity level. At the same time it should be borne in mind that, for example, Karelian dried wood will cost much more than simple freshly cut wood. As an alternative, you can build a sauna with wooden frame walls. Here the total cost of construction will directly depend on the characteristics of insulation and vapor barrier - in any case, such a bath will cost less than a good stone or brick building.

If it is important for you to build a sauna as quickly as possible, it is better to use wood. A log cabin on a pre-prepared foundation can be built literally in 4-5 days. However, there is another side - it will take several years for this sauna to give the shrinkage. The walls of wooden construction due to fluctuations in temperature and humidity will live "their own life" for a long time, and this imposes significant restrictions on the technique of interior decoration and insulation parameters of the steam room.

Avoid such consequences by using frame structures.

It takes the longest to erect baths from stone, because this requires a solid foundation, which, after the execution of the filling should dry for some time. On average, it takes about a month for the concrete to reach the required strength. Those who are afraid of fire, it is best to give preference to non-combustible fireproof stone walls - obviously, this material is much safer than wood.

Stone will be the best choice for those who do not want to overpay for the maintenance of the bath. The fact is that to protect all other materials from rot, mold and fungus in the bath must be maintained at a temperature of at least 15 degrees throughout the year. Thus, the bathhouse will all-the-time consume energy even if no one is steaming in it. This is especially unpleasant when the bathhouse stands on a cottage site, where the standby mode takes about 200 days a year - the extra costs for heat in this case can be very significant.

Minimum energy efficiency has a wooden bath made of timber or logs. This is due to the increased blowing of the walls, in this regard, the wood is significantly loses to buildings made of bricks and blocks. Even in dry windless weather with equal wall thickness in such buildings, the rate of heat loss will be 3 times lower than in all others.

However, wood is irreplaceable from an environmental point of view. But there are also a number of pitfalls. It is very important to make sure that the wood remains healthy throughout the entire operating period. Otherwise, fungus and mold simply will not leave the slightest trace of the original environmental friendliness of the building. To ensure that the surfaces are not exposed to the destructive action of moisture, after each use the room should be dried, it is desirable to establish a warm floor and forced ventilation in the bath.

Successful examples of buildings

Modern baths can be made of a variety of materials.

- Traditionally, wood is used.

- Brick, too, for many years does not lose its position.

- If you want, you can choose more modern available materials - blocks.

About which bath is better, wooden or stone, see in the following video.