All about aerated concrete baths

Today, during the construction of any structures, a person carefully examines the price market of construction materials. Thanks to their wide variety, it is possible to move away from the usual standards and turn to budget options. Among the inexpensive materials included aerated concrete blocks. They have a lot of useful properties, especially in the construction of baths, have multiple quality indicators, and most importantly, do not hit the pockets of the builder.

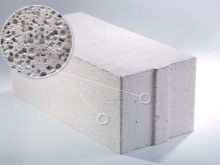

Features of the material

Aerated concrete blocks, which today can be found in the construction market, are designed for the construction of bath complexes. This material has a number of features, thanks to which the construction serves faithfully to its owners for decades.

- Gas blocks are resistant to severe frosts.

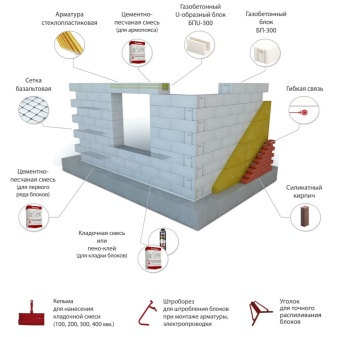

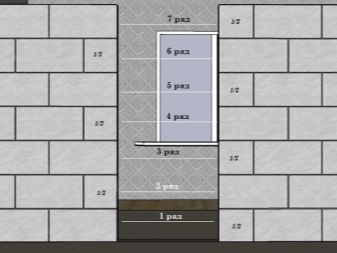

- The blocks have different shapes. U-shaped versions are used to form door and window openings. Rectangular blocks are used to build walls.

- Gas blocks have a porous structure, characteristic of foam concrete. During their manufacture, gas is added to the standard mixture.

- The design of the wall gas blocks has a layer of thermal insulation.

When building bath complexes of gas blocks, the optimal thickness of walls ranges from 25-40 cm. For the northern strip, the width of the walls should be at least 60 cm.

Pros and cons

Specialists in the field of construction with great pleasure are taken to the construction of baths from aerated concrete. As they claim, building structures from aerated concrete blocks - solid pleasure. And in general, this is understandable, aerated concrete unpretentious, easy to handle, the main thing to know the technology of working with them.

Having carefully studied the material, I was able to make a list of its advantages, which everyone who wants to build a bath from gas blocks should know.

- Gas concrete blocks are so easy to handle that for the construction of structures you can not hire a team of workers, and do everything with your own hands.

- In terms of price gas blocks are most affordable, and the period of operation of the building is quite high.

- Structures made of gas concrete blocks are similar in strength to brick structures and stone buildings.

- Aerated concrete has a high level of resistance to fire.

- Small rodents and harmful microorganisms cannot exist inside aerated concrete structures.

- Each individual gas block has an acceptable weight.

- Gas blocks do not rot or decay.

- Gas concrete is an environmentally friendly material.

But in addition to the advantages, there are several significant disadvantages, which often make builders reconsider the use of this material.

- The duration of release of absorbed moisture. Windows and artificial ventilation will not help. It is preferable to use additional waterproofing on all sides of the structure.

- There is no clear guarantee for the service life of structures made of gas blocks.

- The interior space of the finished bathhouse looks unconventional. You will have to make additional investments to make an appropriate design.

What foundation to choose?

Baths built of gas blocks are lightweight structures that do not require the creation of a reinforced foundation. A shallow foundation is allowed on different types of soil. To date, there are 3 types of foundations used for the construction of gas concrete baths.

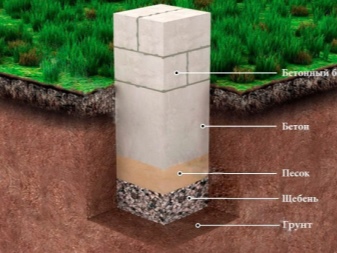

- Shallow-depth strip foundation. The most common base used in private construction. And all thanks to the simplicity of its creation. It is only necessary to take into account the peculiarities of the site and the mass of the future construction. After making an appropriate marking, you can begin the work.

- Pillar. Outwardly, this type of foundation resembles a grid of columns, which are installed under the load-bearing walls of the future construction. The optimal distance between the posts is 150-200 cm. To give stiffness to the columns, the columns are combined with an overhead beam, which will play the role of additional support for the walls. The columns themselves can be brick, concrete, stone or steel. Each option is suitable for a certain type of soil.

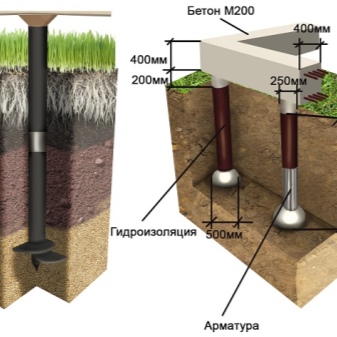

- Pile foundation. This type of foundation is supposed to be used in unstable and too wet soils. The monolithic grill used in the creation of the foundation holds the load of the building, evenly distributing the pressure on the supports.

Adherents of traditional building technologies prefer the old method of foundation creation. They dig trenches of appropriate size, hammer in the corners of the excavation, make a frame, install a formwork and pour concrete. In rainy weather, it is covered with a film and left for a few days until the concrete dries completely.

The main thing, when pouring the foundation, leave outlets for communications.

What to finish with?

It is one thing to build a bath out of aerated concrete blocks and quite another to finish it off. Some people leave the exterior of the bath without any changes. But even from the aesthetic side such a decision would be unwise. Even for guests, the appearance of the building in many ways characterizes the owner. But before considering decorative finishes, it is necessary to know a few nuances regarding the insulation of the walls.

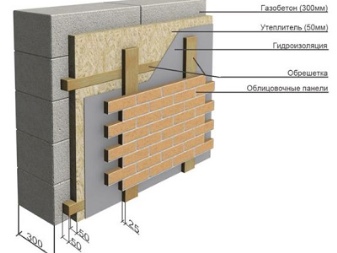

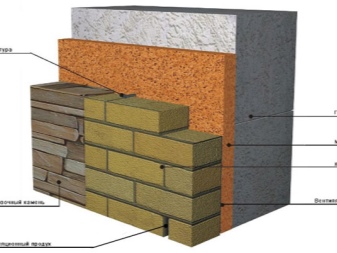

In general, aerated concrete blocks are self-sufficient material that does not require insulation. It is sufficient only to correctly calculate the thickness of the walls. You can use additional thermal insulation. Firstly, the load on the foundation is reduced. Secondly, you get better insulation. And most importantly, the insulation will not be visible, as it is covered by a layer of finish that protects the gas blocks from external exposure.

The outer insulator is mineral wool. Inside, it is preferable to use polyethylene foam. Thanks to a properly thought-out external and internal finish of the gas concrete bath, the main characteristics of the structure are determined. Before finishing, the walls and ceiling are covered with waterproofing. You can use liquid glass, which increases the thermal qualities of the building. The final stage of interior design is finishing with wooden battens.

On the external side of the baths made of aerated concrete require special protection. Initially, the construction is covered with primer, on top of which decorative elements, such as plastic lining, block-house or wood are laid out.

Outside

Many people believe that the external finishing of baths made of aerated concrete blocks is not so important. In principle, it is. Exterior decoration is done for the aesthetic beauty of the site. In order for the gas blocks to take moisture and direct it back, it is necessary to observe one important rule: each finishing layer must have vapor permeable properties. A huge mistake would be to finish exterior walls with sheets of foam plastic.

This material is very dense, does not allow moisture to pass through, which means it does not allow moisture produced in the form of steam inside the room to pass outside. Liquid collects in the gaps between the gas blocks and the foam plastic, which causes dampness, mold and fungus can appear. And if the situation is not corrected, the walls will soon start to collapse.

From inside

People who do not know the construction technology and characteristics of materials, claim that gas blocks are afraid of water and humid environment, and in winter time and even split from the frost. This, of course, happens, but only if the construction was not taken into account construction requirements.

Aerated concrete blocks are a strong material, which has a complex texture that lets moisture through. That is why one side of each cellular block absorbs moisture, and the other side brings it out. Unlike other materials, aerated concrete blocks do not get moldy and are not attacked by fungus. During cold weather, the accumulated liquid freezes into ice and expands, and the fine pores of the material are not affected. Accordingly, no cracks and splits occur.

Work on the interior finish of the bath begins with the laying of waterproofing of the walls and ceiling. When laying waterproofing material, it is necessary to overlap sheets with each other. Then wooden battens are installed over the waterproofing, which creates a ventilation gap between the interior decor and the base of the walls. Wooden panelling is attached to the purlins, but it must first be treated with a moisture-repellent compound.

Flooring is most often decorated with tiles or wood. Tiles in this case, quite a dangerous material, as its slippery coating has a high probability of an accidental fall.

But before laying out the floor decoration, it is necessary to make a concrete screed. The main thing is not to forget to leave the communication outputs.

How to calculate the amount of material?

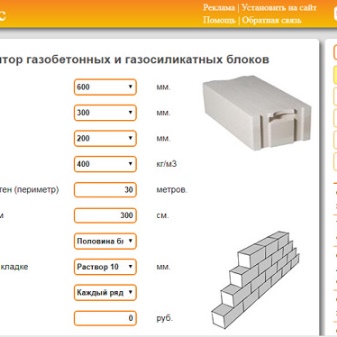

Wishing to erect a sauna of aerated concrete on their plot, many turn to specialists, pay them for their work. But to calculate the amount of material required can even be a novice builder. It will only need access to the Internet and the exact parameters of the desired building.

On the Internet you will need to find a calculator for the calculation of aerated concrete blocks and enter the necessary parameters in the appropriate boxes of the system. Those who encounter such a calculator for the first time, an explanation of each individual item is provided.

Initially, it is necessary to enter the parameters of the building or individual walls. In this case, it should be understood that in the construction of a bath or other structure can be used several sizes of blocks. In order not to make a mistake, it is necessary to be guided by the construction project.

- In the first point you must enter the length of the walls. When calculating the outer sides, you can put the data of the entire perimeter of the structure and the internal load-bearing walls. Internal partitions are calculated separately.

- In the second paragraph, the height is put. The value must correspond to the meter value.

- In the third paragraph the presence of gables must be indicated. If the answer is positive, additional paragraphs are opened, which require entering the length and width of each individual pediment. It is worth noting that gables may have different shapes, which means there may be a slight error in the miscalculation. But thanks to the laid in reserve, this nuance will not be felt.

- In the fourth point it is necessary to remove the window openings from the general masonry walls. After confirming the calculator's proposal, additional items will open, where the dimensions of the windows are entered.

- According to a similar scheme, the fifth point of the calculator, which affects the door openings.

When you enter all the values, the calculator calculates the total work area for a certain type of blocks.

The next section of the calculator is to specify the parameters of the selected aerated concrete blocks. In this case the parameters of the selected material will be considered.

- The first paragraph specifies the dimensional parameters of the block. As the manufactured blocks have several variants of length, width and height, it only remains to choose the necessary dimensions from the pop-up list.

- In the second paragraph you should specify the brand of the blocks you are interested in. This information shows their density.

- In the third point you should specify the factory packing volume in cubic meters.

- In the fourth point the cost of the local manufacturer's gas blocks is put down.

Then the calculator offers to make a calculation according to the specified data with and without the allowance. On the account of the reserve offers to choose either 5% or 10%.

Then the results of the calculator calculation are summarized. The result is displayed in five values:

- 1 - the required number of blocks of the selected format, taking into account the reserve;

- 2 - total number of blocks in cubic meters;

- 3 - number of pallets;

- 4 - weight of blocks, so you can determine the method of transportation;

- 5 - material price according to the manufacturer's quoted price.

If you want, you can send the calculation to e-mail. Once you understand the rules of filling in the calculator, you can conclude that the calculation technology described by many experts is simple and does not require any special knowledge.

Examples of successful projects

To date, a lot of interesting projects of bathing complexes erected both for private use and for commercial purposes have been realized.

- A bath-house with an open terrace looks very interesting. Visitors will appreciate the opportunity to experience bliss after the bath sitting on the terrace in a rocking chair and admiring the beautiful view.

- And this is a one-storey detached bathhouse with a furnished attic. Those who like to experience soft steam and relax with friends will be able to visit a similar complex, and after the procedures go up to the attic, where you can spend time with a pleasant conversation.

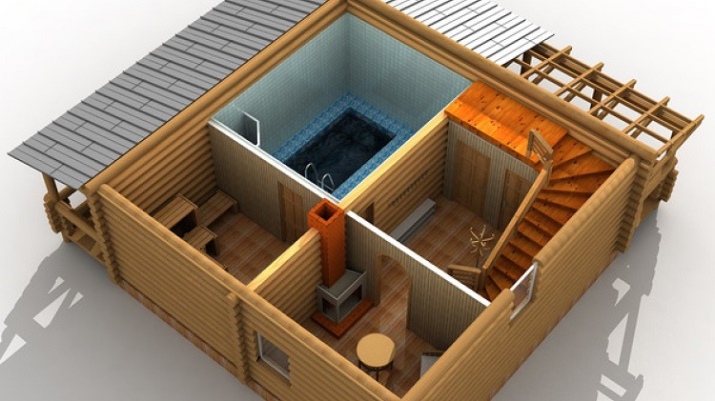

- And this is what the project of the two-storey sauna with a room for rest on the second floor looks like. As can be seen, the lower level has an entrance part, a steam room and a swimming pool. From the dressing room you can see the stairs upstairs, where you can arrange the room according to any preferences of the owner.

The following video shows you the construction of a bath from aerated concrete.