All about the baths of blocks

Today, the bathhouse performs not only hygienic functions. In it you can rest, relax, meet with friends. Building from blocks is built quickly and relatively inexpensive. In the article we will tell you what kind of blocks there are and how to properly design and build a bathhouse on your plot.

Pros and cons

The block bathhouse equally contains its pros and cons. Block products have an uneven structure and are made of different materials, most often for the construction of baths use aerated concrete, aerated concrete and expanded clay lightweight concrete.

Each material is good in its own way, and their disadvantages are also different. To be objective, we need to consider the pros and cons of each species separately.

Aerated concrete

Aerated concrete products are considered a controversial material for the construction of the bath, they have many advantages, but their disadvantages are also significant. Let's start with the advantages.

- It is pleasant to deal with aerated concrete, it is simple to handle and easy to install. This material is preferred by those who build a bath on their own.

- Will please and the speed of assembling the walls. Due to the volume of blocks the construction of the bath is many times faster than brick or wooden buildings.

- The convenience of self-assembly is due to the low weight of the porous material. Aerated concrete walls do not need a powerful foundation, and the construction of the blocks can be done without special equipment.

- The material perfectly withstands high temperatures, especially if it has been autoclaved, it acquires high thermal resistance, exceeding the characteristics of bricks by three times. This means that the material heats up quickly and keeps heat for a long time, saving the owners energy resources.

- Thanks to its heat-resistant properties, a minimum of insulation will be needed for the bath.

- Aerated concrete is not less strong than bricks or logs, so you can build a building with it up to three floors. And with the arrangement of the slab, the bath will withstand a dense layer of thermal insulation.

- Blocks are resistant to mechanical stresses, they do not rot and do not deform over time.

- They are not afraid of mice, insects and other pests, the material is protected from fungus and bacteria.

- Aerated concrete consists of natural components, it does not emit toxic substances and is an environmentally friendly material.

- A big plus is the cost of the blocks. Such a sauna will be several times cheaper than that made of brick or wood.

No matter how many advantages gas concrete has, it has quite significant disadvantages.

- The biggest problem for the bath is the ability of the material to easily absorb moisture and not give it back for a long time. In addition to waterproofing, you will need a good ventilation system of the object. You can think about the presence of windows, but they will lead to a total heat loss of the room.

- Durability of aerated concrete has not yet been tested in practice, since the material for the construction market is new and has not been able to pass a long service life.

- In addition, aerated concrete walls do not "breathe", in this they are strongly inferior to the wood and brick. Poor vapor permeability makes the microclimate far from comfortable.

- The foundation of the bath will require special waterproofing, and the walls will need internal and external finishing, which will affect the cost of the building.

Foam Concrete

The characteristics of foam concrete have certain similarities with aerated concrete, this can be seen by considering their positive and negative sides. Let's start with the advantages.

- Foam concrete refers to light materials, it does not build a high-rise building, but for the bath, this characteristic is good for several reasons: you do not need to spend money on an expensive foundation and you can build the object with your own hands, without special equipment.

- Thermal insulation of foam concrete is so high that it can compete with wood.

- The blocks are easy to handle with a hand tool and not difficult to install.

- Foamed concrete refers to absolutely non-combustible materials, which is important for a building such as a bath.

- Blocks easily absorb moisture, but with the right ventilation system they have the ability to quickly part with it.

- The composition of foam concrete includes environmentally friendly components, which guarantees its safety.

- The use of adhesive mixes makes the joints and seams airtight.

The disadvantages include the following points:

- the ability to absorb moisture for the bath is not an appropriate characteristic;

- tightness should be provided with adhesive compositions, and this is an additional cost;

- mechanical resistance of the material is not at a high level, even mice can damage it, in general, this fact can affect the longevity of the building;

- Moisture retention can lead to the infestation of fungal formations on the walls, even at the stage of construction of the building will have to treat antiseptic agents.

In addition, the foam concrete bath requires finishing works. But even with the cost of trim, preservative and glue composition, the construction will be many times cheaper than brick or wooden building.

Claydite concrete

Unlike the blocks described above claydite concrete does not absorb moisture, which is very important for such a construction as a bath. The material has other important advantages.

- Blocks are large, but weigh a little and are well assembled, which allows you to build a bath quickly by yourself. The building material does not require any special mortars, it is fastened with ordinary cement.

- Blocks are endowed with low thermal conductivity, thanks to this characteristic, you can save on insulation of walls and roofs.

- Fire resistance claydite concrete ensures the safety of the building with a stove and a live fire.

- The material withstands low temperatures and is suitable for the northern regions of the country.

- Fungus and mold do not live on expanded clay concrete walls.

As with any building material, expanded clay aggregate concrete has its negative sides:

- blocks are fragile and light, suitable only for one-story construction;

- expanded clay aggregate blocks do not look aesthetically pleasing, you will need decoration inside and outside, but even these costs will be inconspicuous compared to the cost of erecting a structure of brick.

What kind of blocks can you build with?

The industry has been working on block forms of building material for a long time and provides markets with a large assortment of these products. Many manufacturers deal with the block topic in a comprehensive way, such as, INSI Holding (a group of companies with 20 years of experience) not only produces blocks, but also designs, builds and rents turnkey houses quickly.

For the construction of baths customers prefer to choose lightweight, heat-resistant and cheap material. Some of the most popular types suitable for building baths and saunas include the block products below.

Aerated concrete

The building material is cellular concrete product with pores up to 3 mm, evenly distributed over the entire mass of the product.

It is divided into autoclaved и non-autoclave types. Autoclaved blocks are also called gas silicate. They are made by firing under high pressure in autoclave ovens.

With this treatment, the material changes its characteristics and is more suitable for the construction of baths than non-autoclave analogues.

Foam concrete

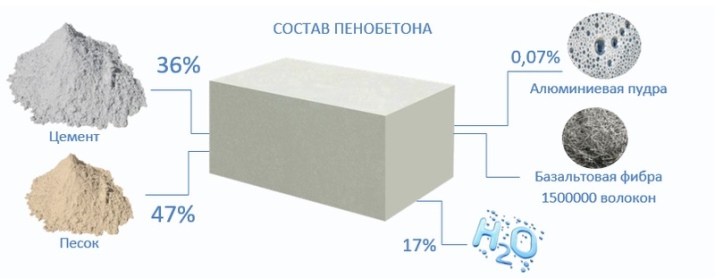

Is a type of concrete blocks. The product is made from cement, sand and water with the addition of foaming agent, which transforms the homogeneous composition into a cellular structure. At the time of curing, voids are formed in the material. This distinguishes it from aerated concrete, whose cellular structure is formed by chemical reactions.

Claydite concrete

The material is obtained by mixing cement, sand and expanded clay. Air-entraining additives make the structure porous and light. As for the construction of baths, it can not be attributed to the best options, it is fragile, absorbs moisture, is afraid of frost, requires finishing work. In addition, the walls are too thick.

There are other block products. Thermal blocks are a three-layer structure with light weight, each part of which performs its function. Baths can also be built from Twinblock, polystyrene concrete, ceramic blocks. The latter are produced as a substitute for red hollow brick, but the size of ceramics is more than twice as large as bricks.

Projects

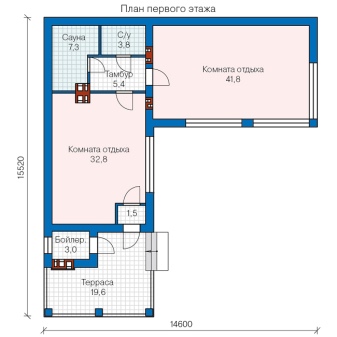

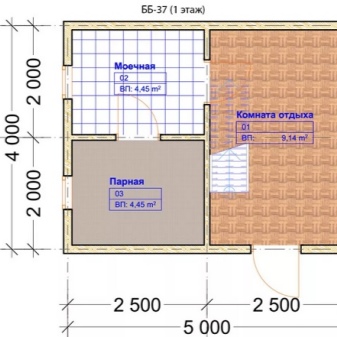

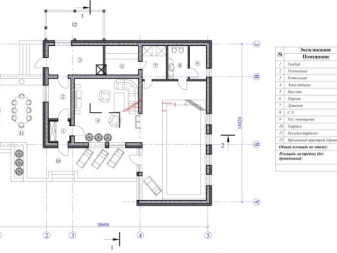

Any construction begins with a sketch, drawing, calculations. You can find a project of a block bathhouse on the Internet, prepare it yourself or use the services of a professional. In any case, the bath must contain at least a steam room, a washing room, a pre-bath and a rest room.

Rest room

It is given to the largest largest room in the bathhouse. The recreation room has a table, chairs, couches, everything you can relax on or have a snack in between visits to the steam room. A large company can spend the whole day in the bathhouse, so it needs a bathroom and a kitchen to spend time comfortably.

If the bath is arranged to meet with friends, in the room set the TV, music system, game systems, and so on.

Steam room .

It may be Consider it the most important room in the bath, for the sake of the steam room and all conceived. Here is the furnace, are arranged beds. Location and configuration of the shelves calculated even at the stage of the project, as for them there are certain standards to ensure convenience and safety while in the bath. They can be arranged in one or two tiers. The upper row allows not only to accept more guests, but also to choose a comfortable temperature for everyone, on the upper recliners air temperature is always higher. When choosing the material for the shelves, remember that they will have to withstand the difficult conditions of the microclimate of the steam room.

The size of the projected steam room will depend on the number of future guests, but it should not have parameters less than 2x2 m, allowing 2-3 people to steam at the same time. At the same time you must take into account the large amount of fuel that may be needed for a too spacious steam room.

Bathroom

Second name of this room is showerAs it is installed in the shower cabin or just a basin with a basin. Even in a compact bath for the washing room there should be enough space. Even in cramped conditions the washing area is combined with a steam room.

High temperature is not necessary for showering, so everyone adapts as he can: some first wash while it is not too heated, others (if necessary to take a shower after the steam room) reduce the air temperature by opening the door to the pre-bath. Part of the problem is solved at the design stage, to do this, the washing area should be lowered to a level below the steam room.

Pre-bathroom

It is between the front door and the warmer room and takes up very little space. It protects the rest of the room from draughts and cold air. The size of the bathhouse is discussed at the design stage. It depends on the land plot, financial investment and the number of people that would use the sauna. For a family of two, a small structure of 3x4 meters is sufficient.

The more people who want to visit the sauna, the greater the scale it will have to be. Sauna with visits in the winter time will have to be well insulated.

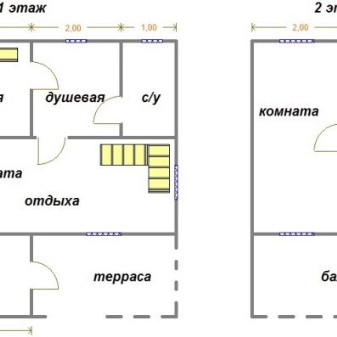

Families who are used to inviting guests and arrange a bathing holiday, combined with barbecue, will need a large-scale complex with a pool, toilet, checkroom. As an addition to the project include a furnace room, kitchen, veranda and barbecue area. We propose to consider several projects of large baths.

- Bath 20x16 m. Contains a large swimming pool with access to the steam room, shower room, lounge and terrace. Lounge (dining room) also has access to the terrace and barbecue area. Additionally the building is equipped with a bathroom, a hall and a vestibule.

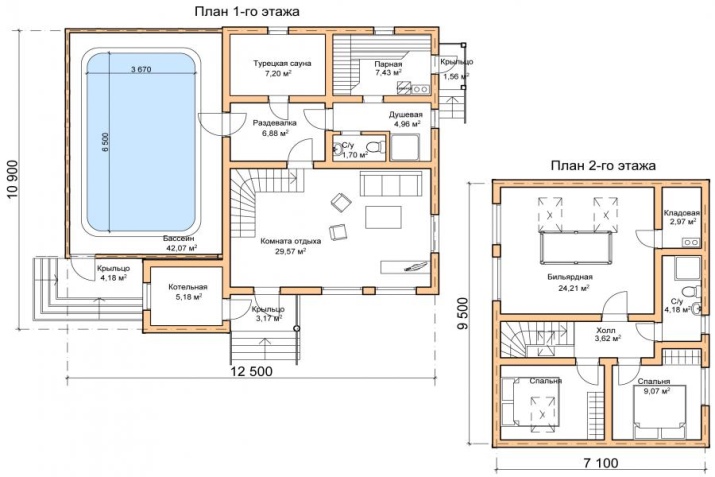

- Two-storey bath (12,5 x 10,9 m) on the combination has the functions of the hotel lodge. The building is endowed with an autonomous boiler. On the first floor there is a big pool with access to the dressing room which leads to the shower room and the Turkish sauna. The floor also contains a steam room, dressing room and recreation room. On the second floor there is a billiard room and two bedrooms. The bathrooms are on both floors.

Now consider the opposite situation, in which There is not enough space for the bath and the owners are forced to reduce the area of the building to a minimum.. This is the case when the steam room is combined with the bathroom. The stove with a heater goes into the steam room, you can heat water on it. The anteroom takes on the function of the changing room and the rest room. In the same room, part of the stove is directed to warm it up somehow. The plus is that such a bath takes very little space and you can save on building materials. But the disadvantage is quite noticeable - it is cold to change clothes in the dressing room, and it is hot to take a shower in the combined washing room.

Compact bathhouse model is not suitable for people with poor health and large families. Wash will have to take turns, each time airing, drying and heating the room anew. Let's consider simple drawings of small baths:

- The simplest construction project contains parameters 3x4 meters. The rectangular structure is divided into two identical rooms. The first room has the functions of a vestibule, locker room and rest room, the second - is directly a steam room and a washing room.

- The following variant of the bath with the size of 3x4 meters assumes Allocation of the washing room in a separate transitional room between the steam room and the anteroom. But in this case the steam room becomes too cramped.

If there are no space and budget constraints, it is better to calculate the sauna with a reserve right away, because the family may increase, and the construction can no longer be changed.

Construction stages

When the project is drawn up, and construction materials are brought to the site, you can start building the bath from scratch. You can always try to make a construction with your own hands, to help you offer a step-by-step instruction.

Preparatory stage

The planned for construction site should Clean the site from debris, remove vegetation, if any. Level all depressions and elevations, make the site flat, suitable for construction work.

Foundation

Almost all block products are made of lightweight materials, so the buildings do not need a powerful foundation. For the bath it is enough to strip or columnar variant.

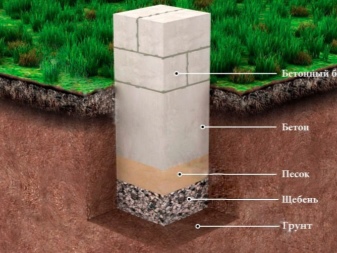

- Pillar foundation will significantly save resources, it is suitable for a small one-story building. It is erected with the help of poles of brick or concrete, which are installed in the corners of the building and at the intersections of the bearing walls. The columns are dug into the ground, leaving only a small part on the surface for joining with the lower part of the bath.

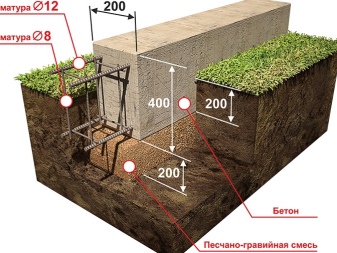

- Ribbon Foundation is needed for a structure with a swimming pool or a two-storey building. It is installed along the perimeter of the bath and along all bearing walls. To pour the foundation, a trench is dug below the frost level of the soil, a formwork is installed, and concrete is poured.

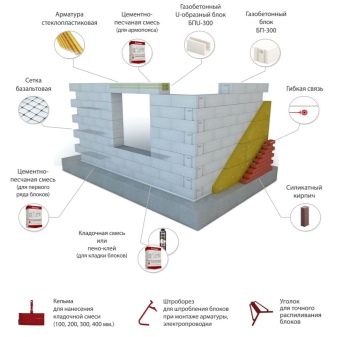

Walls

Masonry walls are made 3-6 weeks after the installation of the foundation (complete drying out is necessary).. Time interval depends on the weather and time of year. A brick plinth with ventilation holes is set over the surface of the foundation. Above erect a waterproofing layer, that is, the melted bitumen is covered with several layers of roofing felt. After the first row of blocks, the beams for the basement slab are laid and the walls are erected. During the work, do not forget about the level and check the quality of masonry.

To strengthen the walls every four rows do reinforcement with metal rods (8-10 mm), with an equal step in a staggered manner. After the erection of exterior walls proceed to the interior walls, they are attached to the load-bearing walls with anchor bolts.

In the upper row of blocks make "pockets" for beams that carry the ceiling overlap.

Roofing .

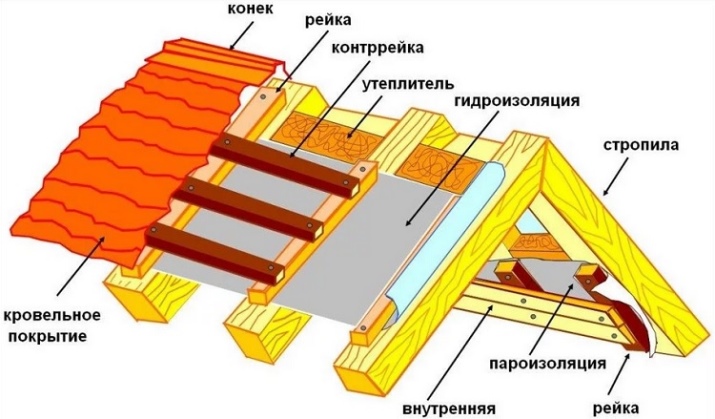

The perimeter of the upper wall block is covered with mauerlat (bar or log), on it rafters are set at a pitch of one meter. At the next stage Install the purlins, which are covered with any roofing material.. For the roof can be used Ruberoid, shingles, shingles, clay roofing or slate.

Warming and finishing

Most prefabricated buildings require insulation. For this purpose, mineral or basalt wool, fiberglass, jute felt is used. When the layer of insulation is laid, you can move on to finishing work. For interior finishing Choose fireproof material, suitable ceramic tiles or some types of cladding. On the outside bath can be encased with siding, plastered or painted.

Finished examples

Externally, block structures are inferior in beauty to wooden beam or brick, but if you try with finishing, the appearance of the bath can even surpass the construction of expensive materials.

- Compact beautiful building made of foam concrete with external finishing.

- Bath with block material.

- Construction of aerated concrete blocks with external plastering.

- Large bath complex built out of blocks.

- Gas silicate block building.

Block products is difficult to compete with the noble wood or brick, but they have a lot of advantages, and the main ones - the ability to build a bath on their own, quickly and cheaply.

In the following video you can take a look at the construction of a sauna made of expanded clay concrete blocks with a slate roof and a weather vane.