Foundation for the bath

Construction of a bathhouse - a process no less responsible than the construction of a house. As in any construction, everything begins with the organization of the foundation. The choice of its type depends on a variety of factors that must necessarily be taken into account.

Features

The structure can be large or not, the most popular variant is considered a 6x4 project. In any case, the foundation for the bath must be strong, resistant to subsidence. In the beginning, it is worth paying attention to the soil, where it is planned to erect a structure. It should not consist of sand or peat, on such soil normal construction is impossible, because there is a swelling, landslide and uneven compressibility. In this case, be sure to organize an additional cushion of coarse sand.

The ideal option for construction - a dry, homogeneous soil, but not every site can find it. More often it is heterogeneous soil with high humidity. Then deepen into the ground to a distance of 50 cm or more.

This is a must, because when the frost arrives, the soil will freeze and simply lift the foundation, while in summer, on the contrary, it will lower it. The result of such differences will be a crack in the wall.

Types

Arrangement of the foundation for the bath is a responsible process that requires experience and certain knowledge in the field of construction. The depth, width and other parameters are already defined by construction standards.

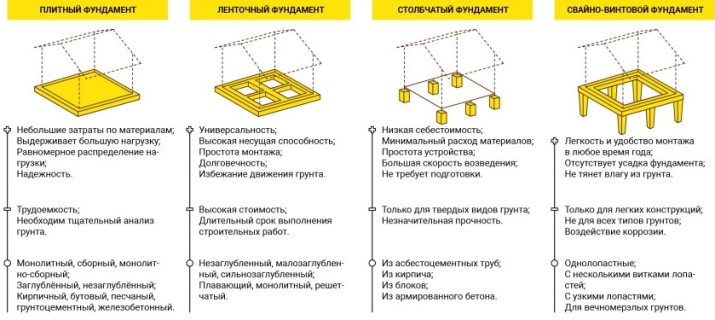

For our country, the following variants are most commonly used:

- ribbon;

- slab;

- columnar.

They are distinguished by their simplicity in the construction and reliability. When choosing the type of foundation, first of all pay attention to the type of soil. If it is clay or loam, a simple strip foundation is not suitable, it is better to use a columnar foundation. Its advantages are obvious:

- no additional lintel is needed;

- strength;

- stability.

If the soil is loose, then this type is no longer used, because heavy materials cannot be used. For a small bath, it is advised to use the strip type of foundation. There are not only rubble stones, but also reinforced concrete blocks. The width of the base is calculated individually. The advantage of this type is its simplicity and a small level of labor costs. Monolith should be used when the soil is weak, prone to swelling. It is considered one of the most reliable options. When building a log cabin, the walls do not need to be fixed and you can revise the project on the fact of erection.

The monolithic slab protects the room from rodents. However, of the options offered, this one is more expensive than the others.

Piled

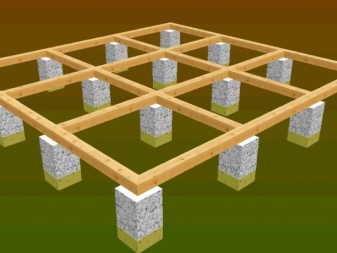

Piled, or, as it is also called, pile foundation type can be made from metal elements, as well as from blocks, columns, which are poured separately. The first step is to mark out the site in accordance with the existing plan. Experts advise using the "Egyptian triangle". Its sides should be 3*4*5. It is in this version that it is easiest to observe the right angles at the base. You can also make it yourself, it is enough to have planks and rope at hand. To make sure that the corners are correct, it will be necessary to check on the diagonal of the area allocated for the foundation.

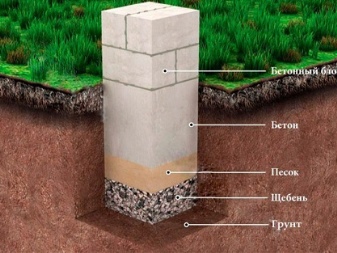

The distance between the posts should not exceed 2.5 meters. It is allowed to use as basic materials:

- brick;

- concrete

- stone;;

- reinforced concrete.

Where, where the walls will be joined, the posts are required to be placed at an angle, which is regulated by the standards of construction. Only in this variant it is possible to break the distance put between the posts, but with the obligatory organization of additional supports. The poles have a standard cross-section - 50-60 cm. If the bath has a light construction, it can be slightly reduced.

The bath can be put on "chairs". This is the popular name for wooden poles. This method is cheaper, the principle of construction does not differ from the concrete or stone version. Taking into account the depth of freezing of the soil, the depth of immersion of wooden piles is calculated. It is worth adding another 250 mm to the existing indicator.

But before the "chairs" are poured with concrete, they are pre-dried and necessarily treated with antiseptic. This is the only way to protect the wood as much as possible from the negative effects of external factors. Additionally, the part that goes into the soil is wrapped with roofing felt, polyethylene, then covered with tar. If the posts are formed from brick or concrete, you should always take into account that the tensile deformation of such structures can not withstand.

In order to avoid problems, the columns are lined up strictly vertically.

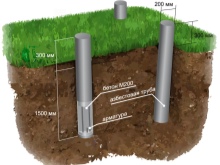

Drilled metal piles are increasingly used. Their advantage is the speed of installation and simplicity. The borehole in the ground should be 1.5 meters. When the soil shows standard bearing characteristics, the diameter is 250 mm. Inside the hole, asbestos-cement pipes with a diameter of 200 mm are installed, sand is poured on the sides and everything is covered with concrete.

Inside the pipe is also poured mortar. Then the pipe is lifted, a small amount of concrete is poured at the bottom. This mortar becomes the base for the pile. After that, the concrete is added inside, but not all the way up to 150 mm. Only when the mixture is compacted can the reinforcement be inserted.

The pile version has many advantages:

- speed of erection;

- There is no need to organize a large group of workers;

- with good waterproofing and compliance with the requirements for construction it will last at least 30 years;

- it is inexpensive.

Since the bath is always installed in the stove, it is the pile foundation that allows you to quickly select its place, without additional strengthening of the base.

When the supports are already standing, they will need to lay the frame. It can be made of:

- wooden beams;

- metal profile;

- channel.

After all, it is covered with board, on top of laying waterproofing and thermal insulation.

Ribbon .

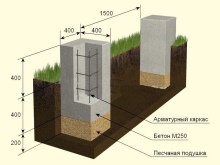

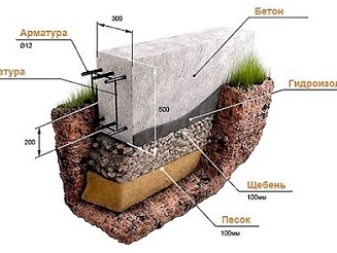

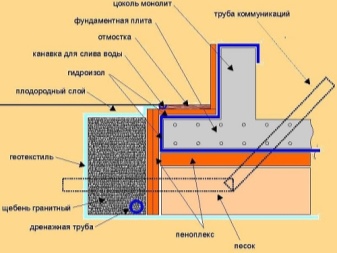

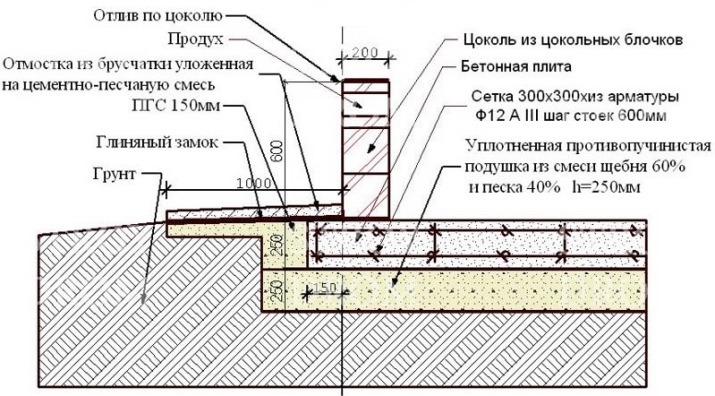

This kind of foundation is practically not immersed in the ground and is a monolith in the form of a strip. The depth is calculated taking into account the quality of the soil. If it is sandy and dry, then the bottom goes into the soil for 600 mm, but taking into account the freezing of the soil layer. If the soil is uneven and wet - the depth of 300 mm below freezing of the soil. As a pillow experts advise using fine white sand. It is laid in three layers, each humidified and tamped.

As a result, the full height of the sand cushion should be 400 mm. Above the poured gravel, a layer which should be on the construction standard 150 mm. Only when the preliminary preparation is finished, the mortar can be poured. When the level of the mixture reaches the surface of the ground, the formwork is installed. The concrete, which has cured on top of the ground, is additionally covered with a waterproofing layer. Bitumen-based products or roofing felt can be used.

Slab

The slab under the bath is organized with a thickness of at least 300 mm. If the area is clay, then pre-fix the base with gravel and sand. For the pillow excavate a pit, the depth of which is 1.5 meters. In the construction of such a foundation, a level is used, which is necessary to level the surface, since there should be no slopes. Monolithic slab is poured with a formwork, but there are special requirements for its rigidity. It is better to use additional supports, so that under the pressure of the cement mortar, the boards do not sprawl.

At the third stage, waterproofing is performed. Not only polyethylene film with a special density, but also bitumen-based coating materials are suitable. When laying such a foundation, reinforcement is necessarily used. Its role is performed by bars, the diameter of which is 14 mm. The length is strictly regulated, it should be 100 mm less than the size of the slab. Metal elements are laid by lattice, then between themselves are knit. Each cage must be 15 to 20 cm. For knitting, 2 mm wire is used, it is allowed to use kapron wire ties.

The grid is formed not one, but two. A 50 mm thick waterproofing layer is formed between them.

Selection criteria

The heavier the construction, the stronger the foundation must be. The shallow-depth strip version of the foundation may not hold the sauna, if it is made of heavy material.

- If the ground on the site is garden, liquefied or forest, then it is better to use the band version. It is also suitable for a wooden frame sauna. Obligatory condition is a sand cushion.

- If there is coarse sand, clay or gravel of small fractions on the site, you need to choose a pole foundation or the same strip foundation.

- Any type of foundation from the described is used on the ground with fine sand, quartz or in the presence of rocky rocks.

- On heaving soils, a shallow foundation is also used. It can be monolithic.

Materials

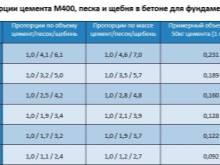

When a monolithic foundation is laid under a bathhouse, it is especially important to pay attention to the brand of cement used. M200 is also excellent for a wooden building. If it is a building with reinforced concrete ceilings made of blocks, then it is better to use M250. In the construction of multi-storey baths use M300.

It is possible to erect the base for the bath from expanded clay concrete material. The ratios for such a mortar:

- cement - 12%;

- sand - 25%;

- gravel - 45%.

All the rest - water and clay. Such a block foundation requires additional waterproofing, but it is also perfectly suitable for the construction of a bath from foam blocks, since they are light.

Sturdy foundation can also be erected from tires.

- First, it will be necessary to make a marking under the dimensions of the future construction.

- At the second stage, the top layer of soil is removed to a depth of 150 mm. All the space, freed from the ground, is covered with a mixture of gravel and sand. The ratio is 1/1. It is mandatory to tamp down such a pillow.

- Pads should be of the same size and height. The foundation will require 20-25 pieces of them. Lay the tires on the perimeter, very tightly to each other.

- After the studs are used, be sure that they were threaded. They will need to be tied to the armature, which is pre-passed through the tires. Studs are necessary to fasten the structure of the beam. Each stud is laid to the depth of the entire tire. The height - at least 25 cm above.

- Reinforcement specialists advise to lay not only along the perimeter, but also diagonally. If you drill holes in the tires, it becomes easier to reinforce. With this approach, there is no need to make additional strapping with an angle or channel.

Another option - blocks of tires, which are sunk into the ground. The cost of building such a foundation is much lower than any other foundation. At the same time, the high quality of the foundation and its strength is preserved. This solution is ideal for a log cabin or even for a house made of wood.

Block base made of tires does not require the use of piles, reinforcement. Marking is carried out in the standard version. Tires are stacked on top of each other in the amount of 5 pieces. It is they that will serve as a support for the log or beam.

One of the advantages of such a foundation - it dries quickly, you do not need to use a lot of cement mortar. After a few days, it is already possible to mount the bath.

Construction stages

Erection of the foundation for the bath with their own hands can be divided into several stages. With a step-by-step instruction, the construction is greatly simplified.

Preparing the site

It is necessary to begin the erection with the preparation of the site. It is pre-cleaned from debris, including stones and trees, if they interfere. In the presence of tall grass, it is advised to remove the top layer. Clean the site with a reserve. On each side, a minimum of one centimeter is required.

Marking

To build a bathhouse, you can't do without the marking for the foundation. The following tools will be needed:

- stakes;

- angle piece;

- twine;

- tape measure.

Stakes are hammered into the corners and connected with string. Angles must be strictly 90 degrees. To check, use an angle, and then check the diagonal. It should be the same, the maximum discrepancy - no more than 20 mm. When everything is ready start digging the trench.

Earthworks

The depth of the trench varies depending on what soil is being built on. Usually for a strip foundation - 50-70 cm. If it is a non-friable soil with a lot of clay or fine-sandy, then the trench is dug to a depth of 1 meter, if the level of soil freezing is 75 cm. When 1.5 m is frozen through, it should be no less than 2 m. When sandy soil is present, the trench cannot be less than 60 cm from the frost level. If a strip foundation is formed, then its width is from 50 cm to 1 meter. If the soil is weak, it is possible to increase the figure to 2 or 2.5 meters. The width of the trench is made with a margin of 20 cm from the set value.

At the bottom of the trench lay a sand cushion with a thickness of 10-20 cm. The first layer is wet and tamped, then pour the next and so on until the required thickness is reached. On top of rubble is placed and again tamped.

Do not do without a pillow. Thanks to it, the building will not warp, and you can prevent the deformation of the walls. Sand additionally protects against temperature differences.

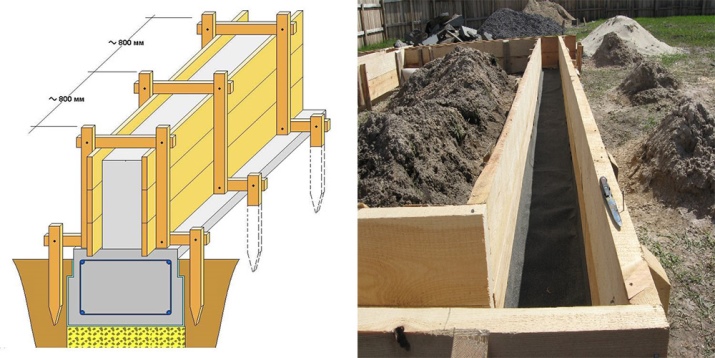

Decking

Shuttering is called a framework, created from boards. Such walls are designed to hold the cement mixture until it hardens and takes the desired shape. All elements are fitted tightly to each other. If there are gaps, the mortar will leak into them. Before installation, the formwork must be cleaned and moistened. The mortar is not poured all at once. Each new layer can not be more than 150 mm. The work is performed on warm days when it is not raining.

Reinforcing

Concrete has sufficient strength, but it is not enough in construction, so reinforcement is used. Metal elements are laid in two layers. Reinforcement is used for this purpose, its diameter can be from 1.2 to 1.6 mm. It is desirable to additionally treat the metal with an anti-corrosion composition. The rods are tied with wire, on the bottom you can additionally lay a brick crumb. If the bath will have a drain, it is organized at the stage of reinforcement.

Pouring

Concrete for pouring can be prepared independently, and you can buy ready-made solution. The second option is becoming increasingly popular. To properly pour it, you need to know a few rules:

- the thickness of the first layer - no more than 200 mm;

- The height of the rise of the sleeve - no more than 50 centimeters;

- necessarily the solution in the formwork pierce with a shovel to remove air, or knock on the boards with a hammer.

In hot weather, the foundation must be watered, in the rains it is covered with a film. In good weather, such a construction dries for at least 3 days. That is how long it takes to remove the formwork, but put the walls not earlier than 3 weeks.

Insulation

Sand is a kind of insulator, but you can additionally fill in claydite along the logs. As insulation is suitable and additional reinforced thin screed. Warm floor - always a warm bath. Additionally, it is worth insulating the backdrop.

Basement finish

The basement is finished for decorative purposes and to protect the foundation from moisture. Today the market offers a variety of decorative materials. What to choose - depends on the preferences and financial status of the owners of the bath. Natural stone and various kinds of panels made of composite materials are popular. Some people simply prefer to make a quality waterproofing of the foundation. For this purpose, bituminous mastics, roofing felt are used.

Separate attention is paid to the foundation of piles. Here, to finish the plinth, you can use plastic panels. They are inexpensive, there are many color solutions. Also suitable imitation beams. It looks beautiful, expensive and goes well with the wooden construction.

Ideal for finishing socle product of sandy concrete. Produce it by dry vibrocompression.

Blind area

Blind area is necessary, it can play the role of a path, then it is made strong, given how many people and how often they plan to walk on it. Such a path around the bath will protect the base from the accumulation of water, but to make it effective, make a blind area at a slight angle. Lay it out of concrete, paving tiles, paving stones and other materials. Be sure to organize an additional cushion of sand and gravel. Depending on the type of soil selected material backing. If this is clay soil, then the monolith of concrete is not suitable. In the described version, it will quickly deteriorate.

Use monolith only when justified, and the thickness of the layer should be at least 150 mm with additional reinforcement. On top of a special tile or stone is laid. When organizing a blind area, tiles made of sandy concrete are used. It is also laid on top of a layer of gravel, but its thickness should be 50 to 100 mm. Some people simply fill the space around the bathhouse with gravel. This material is easy to correct if it "floated", and in addition, small stones muffle splashing during rain. With this kind of backsplash, you can plant flowers and shrubs nearby. Another option is a large fraction of expanded clay.

In the following video you will find a strip shallow foundation for the bathhouse.