All about foil for baths

In order for the bath to perform all the necessary functions, it is necessary to create certain conditions. One of the main characteristics is the temperature regime. To maintain high temperatures, various insulators are used. Foil materials have remarkable practical properties.

Characteristics

Due to the special texture, the material reflects the rays (up to 97%), returning them back into the room. To keep the maximum heat inside the room, it is necessary to use a solid version of cladding. The use of a special foil material allows not only to create the right temperature conditions, but also to save significantly on heating.

Foil is ideal for baths and saunas due to the following characteristics:

- low weight, which does not burden the walls;

- The building material is not harmful to health and the environment because of the absence of emissions;

- foil is not afraid of high humidity;

- at the expense of excellent plasticity process installation is greatly simplified;

- the material easily withstands high temperatures (the maximum temperature of 300 degrees Celsius);

- fabrics do not allow steam to pass through and are resistant to the formation of rust;

- quality product, manufactured according to all requirements, has a long service life.

Another characteristic of the foil product is protection against condensation. Modern manufacturers offer buyers a material that is not difficult to attach yourself. For the work you will need only a standard set of tools. When laying, do not leave gaps and make sure that the foil is not deformed in the process.

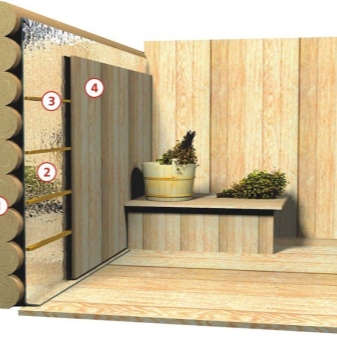

To get the most out of all the material's properties, it is trimmed not one wall, but all the walls in the room. Foil can also cover the shelf. Do not forget that warm air rises up, and a lot of heat comes out through the ceiling.

Note: the properties of the fabrics depend on the technical characteristics of the material. The thickness plays an important role. Material with an index of 80-100 micrometers (micrometers, or microns) will retain heat much more effectively than sheets with a thickness of 50 microns.

What is it used for?

Foil for the bath or sauna is a practical insulation, presented by modern manufacturers in a large variety. Simple installation and a list of positive characteristics have made this type of insulation widely in demand. Its main task is to retain a maximum of hot air in the steam room.

As a rule, To insulate the ceiling and other surfaces in the bath, experienced professionals use thin aluminum foil. The thickness varies from 30 to 300 micrometers. Depending on the type of cladding, the metal sheet can be combined with Kraft paper. Some experts use a combination of skins to achieve the maximum effect.

Despite the widespread use of this type, there are also opponents of foil coating. There is an opinion that this material is almost no use. The fact is that thin metal sheets have a high thermal conductivity, so they can not effectively retain heat inside the room.

Experts from the construction industry, which is not the first year of using such a vapor barrier, say that for a successful result it is necessary to properly apply the material and know about all its characteristics.

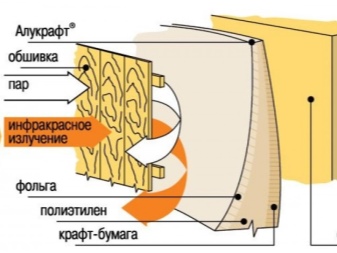

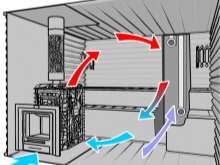

You should not forget about other ways to give off heat. We are talking about infrared radiation and convention. The furnace gives off heat in the form of infrared rays. It is these that are absorbed by the walls of the steam room. If the surfaces are covered with insulation (in our case this is a special foil), the heat rays are not absorbed, and reflected, remaining inside the room.

This material maintains an optimal temperature inside the room is not due to the thickness, but due to the special structure. This unique property of reflective surfaces has long been known and actively used.

Another property of the material, due to which it is used to preserve and reflect the heat rays is an excellent vapor barrier. With durable sheets, it is possible to create an airtight covering that will not let moisture in. This characteristic also helps to maintain a high indoor temperature.

With the proper use of foil for the bath or sauna, hot humid steam will last longer inside the room, maintaining optimal conditions. Such a steam room will be a comfortable place to spend time.

Note: Other uses for this material should not be forgotten. Reflective sheets are often placed behind radiators and stationary heaters. Due to the reflection of the rays, the heat is directed inside the room, rather than being absorbed by the back wall.

Types

Aluminum material, which is actively used for cladding baths and saunas, is presented in a large variety. Before you make a choice, you need to familiarize yourself with the features of each option.

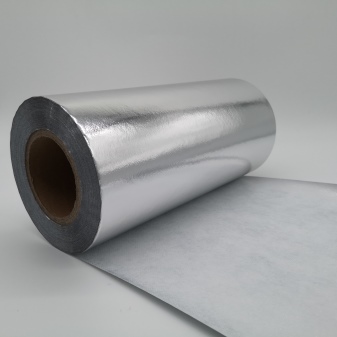

Rolling

The first product on which we will focus, has no base. It is the thinnest type, which has a reduced strength (compared to other types of reflective sheets). Its thickness varies from 0.007 to 0.2 mm. Foil is sold in rolls - 5, 10 and 20 meters in length. The width can also be different - from 1000 to 1500 millimeters.

Metal coreless sheets are often used to clad walls in these rooms. They are mounted on top of other insulation. To achieve the desired effect, the sheets are mounted with an overlap. The joints between the sheets should be securely glued with a metallized scotch tape. The result will be an airtight surface.

Despite the fact that the material can not boast excellent practicality, the maximum allowable temperature is 650 degrees Celsius. When used properly, building foil reflects more than 95% of heat rays. It is not afraid of rust and will help maintain high temperatures inside the building.

Kraft foil

The next option is made on a paper base. Also on sale you can find a three-layer material. In this case, manufacturers combine paper, foil and polyethylene. This type of insulation is called "isolar".

Aluminum foil on paper boasts excellent strength and other high performance characteristics. Experts recommend using this material on log walls. There is no need to combine Kraft foil with other insulation.

It is a completely safe and environmentally friendly material. The thickness index is 0.03 to 1.0 mm. The maximum operating temperature reaches 100 degrees Celsius. If you glue the joints securely, you get a practical and reliable insulator that can reflect up to 95% of the heat. Due to the presence of a fabric layer, installation of Kraft foil is faster and more comfortable, compared to the above option.

The material is more tear-resistant.

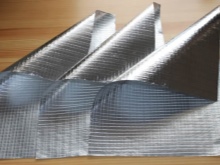

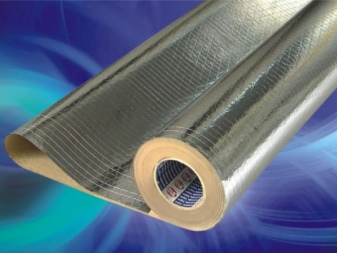

Folar

Effective vapor isolation. The barrier of this type is made of several layers. Between two sheets of aluminum there is a layer of fiberglass mesh. Manufacturers use a material with a mesh size of 4x4 millimeters. The insert in the middle acts as a reinforcing layer.

Due to the special structure of the material retains the declared properties at an extended temperature range - from 60 degrees below zero to 300 degrees Celsius plus. No carcinogens or other hazardous substances are used in the manufacture of folar. Insulator easily withstands high loads, both operational and mechanical.

Reinforced foil comes in 3 types.

- The material retains its qualities at temperatures ranging from 40 degrees below zero to 150 degrees above zero. Single-sided insulation.

- Double-sided cladding. Working temperature ranges from 40 degrees below zero to 300 degrees of heat.

- The third one-sided option features an adhesive backing, which makes it easier to install the covering. Operating temperatures range from 40 degrees below freezing to 80 degrees warm.

Cladding is sold in roll format. The standard length is 50 meters. The width is 1000 millimeters.

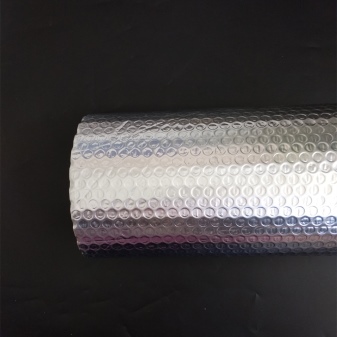

Foil insulation

The penultimate material, which we will consider, is polyethylene foam, combined with a foil coating. The cladding is sold in the form of sheets or rolls. The format depends on the thickness. This product has excellent technical characteristics, such as high strength, noise insulation, shock absorption.

As a rule, foil insulation is used without the use of additional insulation. If you use this product correctly, it is possible to create optimal conditions in the room, using only one version of the cladding.

Foil of this type is often chosen to insulate log surfaces. Also, foil-isolon will be a wonderful addition to the main insulation when working with brick and concrete walls.

Brands offer customers a product with the following characteristics:

- the thickness can be from 20 to 110 millimeters;

- width - 600 millimeters;

- standard length - 1200 millimeters.

Rolls have the following parameters:

- thickness - from 2 to 10 millimeters;

- length - 25 to 30 meters;

- width - 1000 to 1200 millimeters.

The maximum working temperature is 100-125 degrees Celsius.

The product does not deform during installation. If necessary, it is easy to cut it and attach it to the wood grid. For fastening, it is recommended to use a regular construction stapler. If you need to cover metal surfaces, opt for double-sided tape.

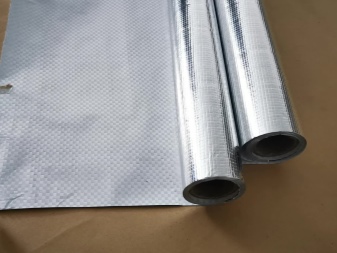

Fleece mineral wool

This option is sold in 2 formats to choose from - sheets or rolls. Manufacturers offer different thicknesses - from 5 to 100 mm. The width and length also vary. Each manufacturer has its own parameters. Mineral wool with an additional aluminum layer can boast an excellent reflective capacity, reaching up to 97%. Operating temperature ranges from minus 60 to 300 degrees Celsius.

Production of this version of the insulation is engaged in many brands. When buying material for the cladding of the bath or sauna, pay attention to the technical characteristics.

What is the best to choose?

To make the right choice, you must be sure to consider certain factors that affect the effectiveness of the material used. It is also necessary to pay attention to the service life and installation features of the cloth. Given the wide choice of insulation, you need to carefully assess the market and decide on one of the options.

If you need to choose a cladding for the battens, it is recommended to make a choice in favor of foil with backing. In this case, the percentage of damage will be significantly lower than when using a single-layer material.

After evaluating the types of foil described above, you can determine what is used as a substrate. Commercial brands use special paper, mineral wool and polyethylene foam. On the shelves of stores you can find cloths reinforced with fiberglass mesh. Adding an additional layer slightly increases the thickness of the panels.

When choosing a foil for finishing the bath, it is necessary to consider the temperature regime. The minimum for modern material should count 100 degrees Celsius. Experts recommend opting for more practical options.

Another important quality of the finishing material for the bath or sauna - resistance to sudden changes in temperature, as well as safe composition, excluding components harmful to health.

To keep a maximum of warm air inside the room, foil should have a high reflectivity.

The required parameter - from 90 to 95%, if it will be below the set value, to achieve the necessary result on the preservation of heat will not work.

Vapor permeability - another important characteristic for foil, used as insulation for the bath. The optimal value - not more than 0.01 g/m² per day.

If you want the material to be easy to install, buy sturdy sheets. The thermal resistance of the foil is important if the metal sheets are connected with other insulation.

To appreciate all the benefits of this product, buy only from trusted stores. Demand a certificate that confirms the absence of dangerous impurities in the composition. It is also recommended to make a choice in favor of known and trusted manufacturers. When ordering foil through the online store, carefully study the specifications of the product.

How to use it correctly?

Before proceeding to the installation of foil, it is necessary to know how to properly mount the insulating material on the walls.

- The first criterion - competently equipped ventilation. In its absence, the thermal insulation characteristics of the insulation will be much lower than those declared by the manufacturer. If the room will not properly circulate air, foil material will be useless.

- It is necessary to take into account the thickness of the insulation layer and compare it to the thickness of walls and other surfaces.

- The fastening of the layers or sheets is of great importance. It is necessary to arrange an airtight covering, covering the joints between the panels. This is especially important if you want to cover the steam room from the inside.

- Special gaps should be made between the layers for proper ventilation.

- When using a stapler, be careful not to damage the integrity of the fabrics with staples. Also, do not forget about safety precautions.

- Experts note that the thermal conductivity of the coating will not show itself in the best way, if you attach the foil to cold surfaces of materials such as concrete, foam concrete, brick.

If you follow these simple and clear rules, the effect of keeping hot air inside the room will be maximum. This insulation is designed so that the process of laying it can be carried out without special skills and tools.

On the differences between 100 and 50 micron foil, see the following video.