Choosing doors for the steam room

To choose the right door to the steam room, you need to understand the peculiarities of this part of the bath, to provide indicators of humidity and temperature in it. For different types of baths, you need your own option, not a universal solution. Otherwise, there may be a threat of heat loss, or condensation will not be properly removed.

Door requirements

Ordinary interior doors to the steam room, of course, will not do. A special purpose unit made according to specific technologies is required.

Separately worth highlighting safety requirements. For example, the door should open only to the outside. If an emergency occurs, it will be easier to leave the danger zone. And also such a door reduces the risk of burns on the hinges of the leaf inside the steam room.

The door unit in the steam room has its own features, there are certain requirements for it.

- It must be tightly mounted in the box, so that sealing was observed, ie, should be perfectly aligned parameters of the block.

- Doors are responsible for the preservation of heat in the steam room, should limit the escape of heat to another area, not allowing it to pass through the leaf or the gaps that were formed near it.

- You should choose the best material, which is not in danger of deformation from excessive moisture and high temperature.

- Frame dimensions are not standard: for steam room doors they should not exceed 180 cm in height, 75 cm in width.

- Internal doors in enclosed spaces are set at a height of 5 cm from the floor. This clearance is necessary for ventilation (but if the complex provides for separate ventilation, a floor-to-door air gap is not necessary).

- The door and frame must not have any elements that can cause burns if the visitor touches them. All interior handles as well as locks in the steam room space must be made of wood. If possible, a window should be made in the door unit. It helps to keep an eye on whether all is well with the visitors of the steam room.

To the choice of door in the sauna, the criteria are almost the same, but it is necessary to focus on the size of a particular room.

Types

In the bath almost always there will be a pre-bath, the washing part, the steam area, the changing room. You can also design additional rooms at the request of the designer. Every room must be equipped with a door. Without proper protection against heat loss in the steam room you can't do without it. The leading materials are glass and wood, but you can also think about a combination of materials.

Wooden

Wooden door - the most popular option. Make such a door from tongue and groove boards, which are then upholstered with clapboard.

You can buy doors decorated with artistic carvings. Their aesthetic qualities increase, but the price rises decently.

For doors use different types of wood:

- Lime - almost ideal material, suitable for the main parameters, and the price of such a door will not be very high;

- Alder - species is not afraid of moisture, does not warp and does not crack, it often cover the interior space of the sauna;

- Aspen - good material, doors made of such wood are protected from cracking and swelling;

- Canadian cedar - not the cheapest material, but its antiseptic properties are worth it;

- Abacha - is a very light wood, and it hardly ever heats up;

- oak - an outstanding material, although the door to the steam room will be heavy and its cost will be above the modest limits of the estimate.

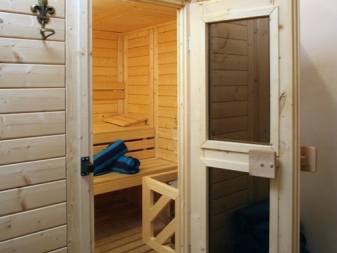

Glass

They have become in demand relatively recently. Used in steam rooms and saunas cloths made of extra-resistant tempered glass. While for Russian baths it's still a rare option, for saunas and Turkish baths it's already a tradition. The glass used for such door blocks has the following characteristics:

- thickness - 8 mm;

- is heat-resistant, ready to withstand a temperature of 300 °;

- is considered safe to use;

- has an affordable price;

- often has a convenient pendulum design;

- it is protected from swinging by magnets;

- easy to care for: well-maintained, quickly cleaned.

In order not to embarrass anyone, order in a steam room is usually a door of tempered frosted glass with safe fittings.

Doors in frosted design have a surface that is "fogged" by chemical acid etching.

Such material cannot actually sweat. If the product is from the cheap category, the frosted glass in it is made by standard abrasive grinding, and this can give serious scratches. The glass slab will not be particularly durable.

Combination

In this case, the door consists of wood and glass, this combination is aesthetic and affordable. In the frame of high-quality wood make an inset window. The parameters of such a window is determined by the customer. There are inserts that are almost the size of the entire canvas, and there are interesting miniature glass inclusions.

It should be noted that many craftsmen do not want to put ready-made design and make the door themselves. More often it is a solid wooden door, but craftsmen also make combined designs.

As for hardware, hinges, handles, the question of security is especially important. Plastic handles are not used, it is preferable to make them wooden. Hinges can be bronze, brass, aluminum or stainless steel.

Dimensions

In order for the steam room to function properly, the steam room must keep hot air well, if we are talking about the sauna. If we are talking about the bath, there should be a good hold a mixture of steam and hot air. The hottest layers of air are under the ceiling. Therefore, the smaller the size of the door, the better the bath will function.

The standard size is considered 150 by 60 cm, in country baths such a low opening is almost always. In the city bath more often it increases to 180-185 cm, because the main share of the heated air heater gives only near the upper shelves.

If the bath is Turkish, the size of the door is not so crucial, the main thing - to comply with the design of the ventschlille. Through it the cold air will dilute the very humid hot air.

How to make your own hands?

If you make the door yourself, you can save a lot of money. In addition, it is not as hard as it might seem at first glance. According to average calculations, the materials will cost 2-3 thousand rubles, the fittings will not cost very much. And the finished door is estimated at 8-10 thousand rubles.

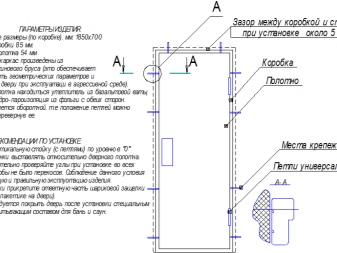

You need to look closely at the schemes: there are a lot of them in the public domain. You should choose a completely understandable option, which does not cause questions, technically convincing. People with experience simply look at successful models of ready-made doors (from manufacturers with a good reputation), make their scheme based on what they have seen and actually make a counterpart.

An ordinary tongue-and-groove board can be used to make a great door. It is good if it will be lime. If making a door with insulation, it is better to opt for coniferous wood. The manufacturing process consists of several steps.

- The selected material should be peeled on a planer, trimming to size according to the calculated dimensions.

- Tongue and groove boards should be glued, tightened with screws into a common prefabricated panel.

- When the glue dries, the workpiece is sent to grind the planes and ends. Do not forget about the removal of chamfers and corners.

- On the side of the workpiece, facing the steam room, make a deck of foil polyethylene foam, which is closed with cladding.

- Insulation is usually stretched and fastened with special staples, and then close it with slats of wood (aspen will do) or plywood of lime. The assembled panel on the back side is strengthened by 2 horizontal bars. The master cuts 2 "needles": this is the name of the profiled bars, which have a trapezoidal cross-section. Fasten the crossbars to the shield of the manufactured door should be using slots, they must match the profile of the "needle". The bar has a wedge shape, and therefore it is easy to wedge and tighten the boards, forming a strong shield.

The next point is to assemble the frame of the door leaf. A good box comes out of oak or cedar plank, timber. In principle, any type of heavy wood will do. The main thing is that it should be eco-friendly and not emit volatile substances. Ready-made cloth should be laid out on the surface, to the ends of it to attach the prepared parts of the vertical sides of the box. At this point, the master makes a marking for the grooves for installation.

In the corners of the side panels will be connected to the threshold and the upper crossbar. The connection is used either studded or in half a bar.

The master makes a notch corner joint grooves on all parts of the blank box, then collects the bow around the door and adjusts it to the size of the latter.

Next, proceed to the marking of the hinges: for the door to the steam room use furniture non-disassembled hinges. Since any wooden door is subject to shrinkage, experts advise leaving a shrinkage gap on the bottom edge of the door. The box with the door is laid horizontally - it is necessary to attach the hinges to it, to transfer the drilling markings on both parts. Then the master cuts chisel grooves on the door shield (on the hinge contour), and finally, fixes the parts on the leaf with self-tapping screws.

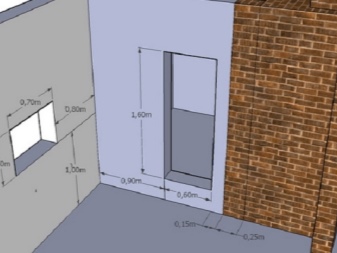

How to install?

This operation may well be called particularly responsible. The installation process begins with the assembly of the bow or box. If there are no mistakes in the assembly, it will be easy to hang the leaf. Installation of a wooden door for the steam room is a step by step.

- It is necessary to cut an opening in the wall. He usually first sawed with a grinder or chain saw (what is convenient). Cut out exactly a rectangular opening, which will exceed the parameters of the entrance unit by 20 mm. If the installation is carried out in a wooden wall, do not forget about the jambs and wall dowels.

- The unit with the door leaf inserted inside, you need to fix. For this purpose, the packing of wooden slats on the corners of the box is suitable. Then 2 people lift the assembled structure and transfer it to the finished wall opening.

- Align the door unit is standard, plumb and level (both horizontally and vertically). Then the box needs to be wedged in the opening with timbers, cut in advance. While shrinkage will last, the wooden block to the walls is "tacked" with oblique wedges. If we are talking about stone walls of the steam room, the lutka must be attached with anchors and dowels.

Next, the installation in the steam room with wooden walls develops according to a certain scenario.

- The door frame is disassembled into parts. Parts are inserted sequentially on the wall dowels, made in advance. First the vertical strut is mounted, then the ceiling beam, then the second strut and finally the threshold.

- Parts of the box must be docked, nailed to the walls of the steam room with dowel fasteners. Cover the outside of the box with platbands.

- All that is left is to hang the canvas: the door is again sent to the frame, building level and wooden spacers to raise it so that there is a gap between the threshold and the bottom edge (it is for the exit of condensation).

- Then in the halves of the hinges, which are already installed, insert the appropriate parts. On the bow mark the drilling points, they are fixed with ordinary self-tapping screws.

The glass door is installed almost the same way. But there is a nuance: imported units often come with hinges on the left side of the bow.

This is corrected by rearranging the lower and upper crossbars. But with glass doors equipped with an aluminum frame, the case is more complicated. At the corners of the frame in the end part of all profiles, you need to put embedded elements, and then connect the parts and tighten them with an Allen key.

Then it is necessary to drill holes in the frame for dowels - with them the box is attached to the walls of the steam room. In this supporting frame you need to insert the glass, make a marking and drill the points of hinge fixation. Then comes the installation of awnings. The frame is inserted into the opening, aligned with a laser level, and fixed with dowels. Finally, you can insert the glass and hinge retainers. Completes the work is laying the sealant, the assembly of the handle and the lock.

What to seal with?

There are many options for thermal insulation, you need to choose the right one for your particular room. The materials used are:

- polyethylene foam - strictly foilized;

- foam plastic, polystyrene foam, polypropylene;

- mineral felt or basalt wool;

- horsehair felt mats.

It is strictly forbidden to seal the door leaf with any insulation on the fiberglass basis, on the fiberglass fabric. This also applies to those blocks that are installed at the entrance to the back room with stove heating. If you insulate the bath not with that material, which knows how to "foam", but with fiberglass, its small particles will crumble and scatter shoes throughout the space of the bath.

What are the best doors for the bath, see below.