Wooden floor in the bath

Since time immemorial, floors in rural baths were made of wood, and today they have not lost their relevance. The only thing that some owners of modern baths add to the traditional construction - is to insulate them with extruded polystyrene foam or other modern material.

About the features of the decking in the bath we will tell in our review.

Advantages and disadvantages

The main advantage of any wooden material is its ability to retain heat. Wooden flooring does not let the heated air outside the washing room or steam room - this allows you to repeatedly reduce the financial costs for the arrangement of a warm floor. In addition, wood - a natural eco-friendly material, moreover, very pleasant to the touch.

However, wood also has its disadvantages, they include:

- laboriousness of laying;

- Increased consumption of construction materials;

- the high cost of finishing;

- the need to organize drainage;

- The need to create special ventilation holes in the basement, the arrangement of ventilated basement.

In addition, to the disadvantages of wood floors can be attributed short-lived timber coating - this problem will not solve even the highest quality processing protective impregnations.

Overview of types

The arrangement of wooden flooring in the rooms can be different, respectively, for it uses different materials, different techniques of work.

Leaking

There are several options for the design of the wooden floor in the bath. One of the simplest ways is a leaky floor. This design is common in bathhouses built on cottage plots, because it allows you to wash and steam only during the warm season.

A distinctive feature of the leaky floor is the lack of drainage to remove dirty water from the surface. Boards here are laid with a small gap, so all the moisture flows through the cracks directly into the ground.

The advantages of a leaky floor include:

- high speed of installation work;

- low cost price;

- significant savings on the implementation of hydro-and thermal insulation.

Among the disadvantages are:

- the impossibility of use in the winter season, as well as in regions with a cold climate;

- short service life and the need for regular renewal of the coating.

The service life of such a floor is 5 years - after this time it must be replaced.

Seamless

In places of permanent residence, the owners of the bath give preference to seamless technology, because they perfectly retain heat in the bathing and steam rooms - this makes the technology everywhere in demand. However, it also has its disadvantages:

- labor-intensive laying;

- Increased consumption of building materials;

- the high cost of finishing;

- The need to equip ventilation in the basement.

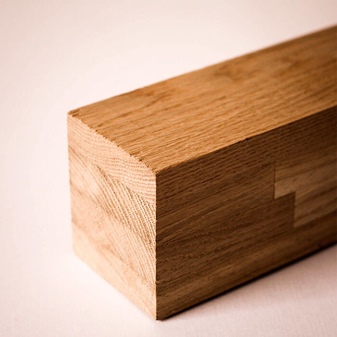

Materials

Depending on the option of flooring in saunas and baths, a variety of materials can be used. For example, leaky floors are traditionally made of unpainted terrace hewn wood, and sealed - of tongue and groove.

Most often pine is used for the floor. Pine is the most budget-friendly and therefore affordable material that is popular in wood construction. If pine has been dried qualitatively, it will not warp or crack. However, this material has no fungicidal component, so it can not resist the adverse effects of fungi and parasites that destroy the wood from the inside. That is why pine boards are very rarely used to decorate the floor in the bath.

All conifers have a significant disadvantage - the presence of resinous passages. At high temperatures, the resins begin to protrude on the surface of the flooring, and this causes burns on human skin. However, it should be noted that this defect is usually short-lived, and after 5-7 uses of the sauna room "tearfulness" completely stops.

As for the rest, conifers consist of only advantages. Thus, the resins that make up the wood fibers are a natural antiseptic.

Due to this property, the wooden floor surface is reliably protected from rotting processes, fungi, mold and other pathogens, rapidly developing in a humid and warm environment.

Let's highlight the features of other wood species as well.

Larch is a strong and very durable material. The fibers contain essential oils that have beneficial effects on the human body, they are especially useful for the cardiovascular system. Larch has pronounced antimicrobial characteristics, so the material is protected from fungus and rot. The only disadvantage of this material is its high cost.

Oak - despite its durability and strength, it is practically not used in the construction of baths. The reasons for this are labor-intensive processing and the substantial weight of the construction. Equally critical is the fact that oak boards begin to crack when the temperature fluctuates frequently.

Cedar is quite a popular option in the construction of baths. It is distinguished by its noble appearance and pleasant texture. The material retains its integrity for a long time, it does not dry out, does not crack and does not deform, and most importantly - it does not rot and is not covered with mold. Cedar contains useful essential oils that have medicinal properties and beneficial effects on human health.

Lime is an optimal raw material for wet rooms.used in the construction of classical baths in the villages since time immemorial. Linden has medicinal characteristics, has a healing effect on people with a weak immune system, liver problems, as well as the propensity to respiratory diseases. At the same time, such a board has its disadvantages, namely, it is exposed to the formation of rot and fungus.

Aspen is an easy to work with and a cheap kind of wood. If properly processed, this material does not deform or fall apart during use. However, it is not recommended for the basis of the floor in the bath and steam rooms, because under the influence of elevated temperatures the wood quickly changes its color and darkens.

And you can also choose poplar for the device of the wooden floor in the bath - it is a practical and cheap material.

Features of installation

The technology of installation of a leaky and sealed floor is different. Make a nonleaking floor with your own hands is more difficult, all the work consists of several steps:

- arrangement of the water catchment - installation of a reservoir to take the liquid to the drain;

- The design of sand and gravel cushion for screed;

- concrete screed with a thickness of not less than 5 cm;

- waterproofing of the coating;

- carrying out the logs and the subsequent laying between them mineral wool, expanded clay, foam plastic or any other insulator;

- secondary waterproofing;

- finishing frame rough floor;

- Finishing of the finishing floor - it should be decorated with a slight slope in the direction of the drain, fix it with nails or screws.

To cover the floor, usually use tongue and groove edged boards with a thickness of 3 cm. In this case, the joists are a wooden bar with the parameters of 50x50, 70x50 cm, and the beams - these are logs 100x100 mm and a little larger.

Formation of a leaky floor is less labor-intensive. To begin with, it is necessary to level the site, then equip the base - to do this, it is filled with gravel and tamped together with compaction.

Next, the installation of beams is performed. Please note that before laying they should be treated with antiseptic.

Finally, the floor boards are laid. They should be laid so that a gap of at least 3 mm is left between them - this will prolong the life of the wood.

As you know, every bath has three main types of rooms: steam room, shower room, and pre-bath. Each of them has its own microclimate and therefore has its own requirements. In the washing room you can use both types of decking. The main disadvantage here is high humidity, so the owners of the bath will have from time to time to change the floorboards. This must be taken into account when installing the flooring, and provide an opportunity for the dismantling of individual elements of the design, their drying and ventilation.

But the microclimate in the locker room and recreation room is practically the same as in standard rooms with a normal level of humidity and room temperature.

The best option for the design of the floor will be the most simple flooring without drainage.

For maximum ease of work on the installation of wood flooring in the bath, it is desirable to listen to the recommendations of experts.

- The boards must be laid properly so that water can easily flow in the direction of the drains.

- Using large planks avoids excessive water accumulation.

- All boards must be thoroughly dried - their humidity should not go beyond the 13-15% mark. Otherwise, the wood will delaminate, twist, dry out and undergo other deformations.

- It is very important to pay special attention to ventilation. It depends on the presence of ventilation holes in the foundation.

How to protect?

Before decorating the floor in the bath rooms, you need to remember that the wood in them will be exposed to frequent exposure to moisture, concentrated steam, condensation on the surfaces and constant temperature fluctuations. Sinks add to the adverse effects of cleaning detergents. It is also important to consider the effect of soil on the surface of the decking. For example, during floods, water can come in from below and flood the boards. Another unfavorable factor is the high temperature difference between separate rooms. This creates an environment in which pathogenic microflora (fungi and moulds) multiply particularly actively and also stimulates rotting processes in the wood fibres. That is why wood flooring in saunas and baths requires special protection.

All impregnations for wood flooring can be conditionally divided into several groups.

- Antibacterial - prevent the reproduction of pathogenic microflora and protect wood from rotting.

- Hydroprotective - Have the effect of clogging up the wooden fibers. Even with frequent contact with water, the material is protected from degradation.

- Fire-resistant - form a non-combustible layer on the flooring surface. Nevertheless, they can not fully protect the wood from burning, that is, no one cancels the safety precautions.

- Blackout - give only a decorative effect. They often contain moisture-protecting and fungicidal components.

- Bleaching - allow you to perform local treatment in problematic areas.

Additionally, you can fill the surface and joints of the boards with liquid glass - it allows you to keep the performance characteristics of the flooring for a long time.

Note that the use of impregnants is important - they protect the wood from destruction, rotting, burning and discoloration. But they can not fully prevent these processes. In any case, it is better to use preventive measures, namely:

- Ventilate the room after each visit to the sauna;

- Wash and clean the floor of the bath in time to minimize the risk of unhealthy bacteria;

- Heat the room regularly, even when it is not in use.

These characteristics are taken into account not only when choosing the varieties of flooring, but also the type of wood, the type of installation work and the possibility of using waterproofing and insulating coating.

How to install a shed floor in the bath, see in the video below.